The FuTure oF nuclear Fuel cycle - MIT Energy Initiative

The FuTure oF nuclear Fuel cycle - MIT Energy Initiative

The FuTure oF nuclear Fuel cycle - MIT Energy Initiative

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

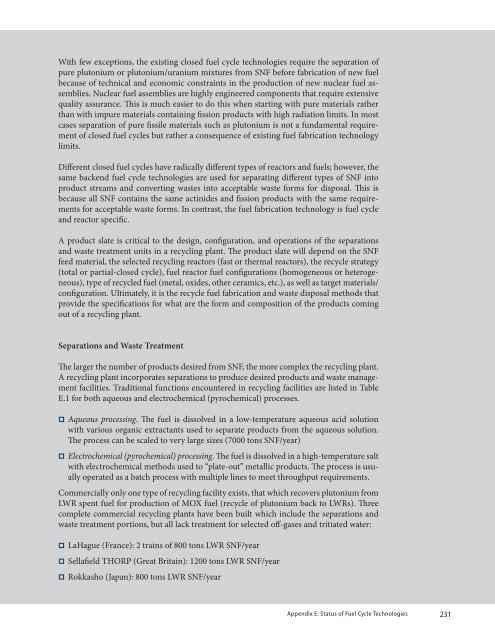

With few exceptions, the existing closed fuel <strong>cycle</strong> technologies require the separation of<br />

pure plutonium or plutonium/uranium mixtures from SNF before fabrication of new fuel<br />

because of technical and economic constraints in the production of new <strong>nuclear</strong> fuel assemblies.<br />

Nuclear fuel assemblies are highly engineered components that require extensive<br />

quality assurance. This is much easier to do this when starting with pure materials rather<br />

than with impure materials containing fission products with high radiation limits. In most<br />

cases separation of pure fissile materials such as plutonium is not a fundamental requirement<br />

of closed fuel <strong>cycle</strong>s but rather a consequence of existing fuel fabrication technology<br />

limits.<br />

Different closed fuel <strong>cycle</strong>s have radically different types of reactors and fuels; however, the<br />

same backend fuel <strong>cycle</strong> technologies are used for separating different types of SNF into<br />

product streams and converting wastes into acceptable waste forms for disposal. This is<br />

because all SNF contains the same actinides and fission products with the same requirements<br />

for acceptable waste forms. In contrast, the fuel fabrication technology is fuel <strong>cycle</strong><br />

and reactor specific.<br />

A product slate is critical to the design, configuration, and operations of the separations<br />

and waste treatment units in a recycling plant. <strong>The</strong> product slate will depend on the SNF<br />

feed material, the selected recycling reactors (fast or thermal reactors), the re<strong>cycle</strong> strategy<br />

(total or partial-closed <strong>cycle</strong>), fuel reactor fuel configurations (homogeneous or heterogeneous),<br />

type of re<strong>cycle</strong>d fuel (metal, oxides, other ceramics, etc.), as well as target materials/<br />

configuration. Ultimately, it is the re<strong>cycle</strong> fuel fabrication and waste disposal methods that<br />

provide the specifications for what are the form and composition of the products coming<br />

out of a recycling plant.<br />

Separations and Waste Treatment<br />

<strong>The</strong> larger the number of products desired from SNF, the more complex the recycling plant.<br />

A recycling plant incorporates separations to produce desired products and waste management<br />

facilities. Traditional functions encountered in recycling facilities are listed in Table<br />

E.1 for both aqueous and electrochemical (pyrochemical) processes.<br />

p Aqueous processing. <strong>The</strong> fuel is dissolved in a low-temperature aqueous acid solution<br />

with various organic extractants used to separate products from the aqueous solution.<br />

<strong>The</strong> process can be scaled to very large sizes (7000 tons SNF/year)<br />

p Electrochemical (pyrochemical) processing. <strong>The</strong> fuel is dissolved in a high-temperature salt<br />

with electrochemical methods used to “plate-out” metallic products. <strong>The</strong> process is usually<br />

operated as a batch process with multiple lines to meet throughput requirements.<br />

Commercially only one type of recycling facility exists, that which recovers plutonium from<br />

LWR spent fuel for production of MOX fuel (re<strong>cycle</strong> of plutonium back to LWRs). Three<br />

complete commercial recycling plants have been built which include the separations and<br />

waste treatment portions, but all lack treatment for selected off-gases and tritiated water:<br />

p LaHague (France): 2 trains of 800 tons LWR SNF/year<br />

p Sellafield THORP (Great Britain): 1200 tons LWR SNF/year<br />

p Rokkasho (Japan): 800 tons LWR SNF/year<br />

appendix e: Status of <strong>Fuel</strong> <strong>cycle</strong> Technologies 231