The FuTure oF nuclear Fuel cycle - MIT Energy Initiative

The FuTure oF nuclear Fuel cycle - MIT Energy Initiative

The FuTure oF nuclear Fuel cycle - MIT Energy Initiative

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

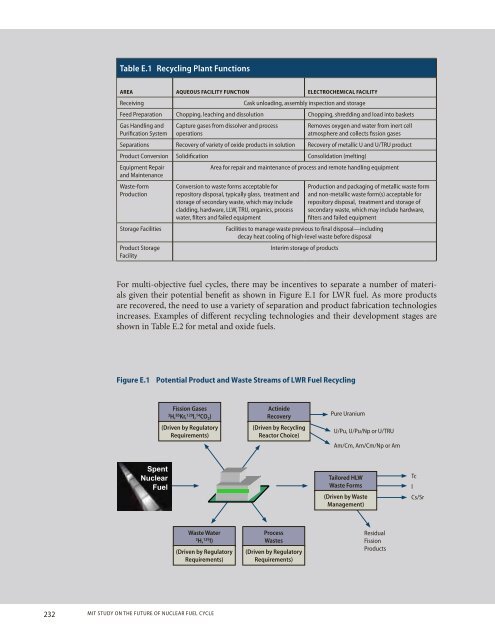

Table E.1 Recycling Plant Functions<br />

area aqueouS FaCility FunCtion eleCtroChemiCal FaCility<br />

receiving<br />

cask unloading, assembly inspection and storage<br />

Feed Preparation chopping, leaching and dissolution chopping, shredding and load into baskets<br />

Gas handling and<br />

Purification System<br />

capture gases from dissolver and process<br />

operations<br />

removes oxygen and water from inert cell<br />

atmosphere and collects fission gases<br />

Separations recovery of variety of oxide products in solution recovery of metallic u and u/Tru product<br />

Product conversion Solidification consolidation (melting)<br />

equipment repair<br />

area for repair and maintenance of process and remote handling equipment<br />

and Maintenance<br />

Waste-form<br />

Production<br />

Storage Facilities<br />

Product Storage<br />

Facility<br />

conversion to waste forms acceptable for<br />

repository disposal, typically glass, treatment and<br />

storage of secondary waste, which may include<br />

cladding, hardware, llW, Tru, organics, process<br />

water, filters and failed equipment<br />

Production and packaging of metallic waste form<br />

and non-metallic waste form(s) acceptable for<br />

repository disposal, treatment and storage of<br />

secondary waste, which may include hardware,<br />

filters and failed equipment<br />

Facilities to manage waste previous to final disposal—including<br />

decay heat cooling of high-level waste before disposal<br />

Interim storage of products<br />

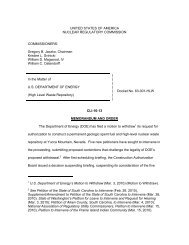

For multi-objective fuel <strong>cycle</strong>s, there may be incentives to separate a number of materials<br />

given their potential benefit as shown in Figure E.1 for LWR fuel. As more products<br />

are recovered, the need to use a variety of separation and product fabrication technologies<br />

increases. Examples of different recycling technologies and their development stages are<br />

shown in Table E.2 for metal and oxide fuels.<br />

Figure e.1<br />

potential product and Waste Streams of lWr <strong>Fuel</strong> recycling<br />

Fission Gases<br />

3<br />

H, 85 Kr, 129 I, 14 CO 2 )<br />

(Driven by Regulatory<br />

Requirements)<br />

Actinide<br />

Recovery<br />

(Driven by Recycling<br />

Reactor Choice)<br />

Pure uranium<br />

u/Pu, u/Pu/np or u/Tru<br />

am/cm, am/cm/np or am<br />

Spent<br />

Nuclear<br />

<strong>Fuel</strong><br />

Tailored HLW<br />

Waste Forms<br />

(Driven by Waste<br />

Management)<br />

Tc<br />

l<br />

cs/Sr<br />

Waste Water<br />

3<br />

H, 129 I)<br />

(Driven by Regulatory<br />

Requirements)<br />

Process<br />

Wastes<br />

(Driven by Regulatory<br />

Requirements)<br />

residual<br />

Fission<br />

Products<br />

232 <strong>MIT</strong> STudy on <strong>The</strong> <strong>FuTure</strong> <strong>oF</strong> <strong>nuclear</strong> <strong>Fuel</strong> <strong>cycle</strong>