The FuTure oF nuclear Fuel cycle - MIT Energy Initiative

The FuTure oF nuclear Fuel cycle - MIT Energy Initiative

The FuTure oF nuclear Fuel cycle - MIT Energy Initiative

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

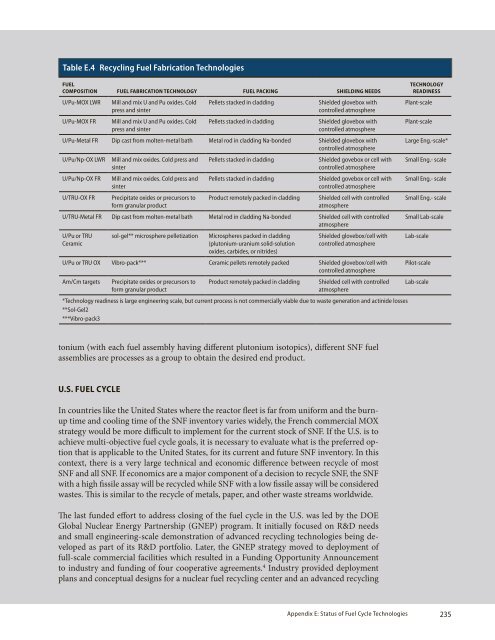

Table E.4 Recycling <strong>Fuel</strong> Fabrication Technologies<br />

<strong>Fuel</strong><br />

CompoSition <strong>Fuel</strong> FabriCation teChnoloGy <strong>Fuel</strong> paCKinG ShieldinG needS<br />

u/Pu-MoX lWr<br />

u/Pu-MoX Fr<br />

Mill and mix u and Pu oxides. cold<br />

press and sinter<br />

Mill and mix u and Pu oxides. cold<br />

press and sinter<br />

Pellets stacked in cladding<br />

Pellets stacked in cladding<br />

Shielded glovebox with<br />

controlled atmosphere<br />

Shielded glovebox with<br />

controlled atmosphere<br />

u/Pu-Metal Fr dip cast from molten-metal bath Metal rod in cladding na-bonded Shielded glovebox with<br />

controlled atmosphere<br />

u/Pu/np-oX lWr<br />

u/Pu/np-oX Fr<br />

u/Tru-oX Fr<br />

Mill and mix oxides. cold press and<br />

sinter<br />

Mill and mix oxides. cold press and<br />

sinter<br />

Precipitate oxides or precursors to<br />

form granular product<br />

Pellets stacked in cladding<br />

Pellets stacked in cladding<br />

Product remotely packed in cladding<br />

Shielded govebox or cell with<br />

controlled atmosphere<br />

Shielded govebox or cell with<br />

controlled atmosphere<br />

Shielded cell with controlled<br />

atmosphere<br />

u/Tru-Metal Fr dip cast from molten-metal bath Metal rod in cladding na-bonded Shielded cell with controlled<br />

atmosphere<br />

u/Pu or Tru<br />

ceramic<br />

sol-gel** microsphere pelletization<br />

Microspheres packed in cladding<br />

(plutonium-uranium solid-solution<br />

oxides, carbides, or nitrides)<br />

Shielded glovebox/cell with<br />

controlled atmosphere<br />

u/Pu or Tru oX Vibro-pack*** ceramic pellets remotely packed Shielded glovebox/cell with<br />

controlled atmosphere<br />

am/cm targets<br />

Precipitate oxides or precursors to<br />

form granular product<br />

Product remotely packed in cladding<br />

Shielded cell with controlled<br />

atmosphere<br />

*Technology readiness is large engineering scale, but current process is not commercially viable due to waste generation and actinide losses<br />

**Sol-Gel2<br />

***Vibro-pack3<br />

teChnoloGy<br />

readineSS<br />

Plant-scale<br />

Plant-scale<br />

large eng.-scale*<br />

Small eng.- scale<br />

Small eng.- scale<br />

Small eng.- scale<br />

Small lab-scale<br />

lab-scale<br />

Pilot-scale<br />

lab-scale<br />

tonium (with each fuel assembly having different plutonium isotopics), different SNF fuel<br />

assemblies are processes as a group to obtain the desired end product.<br />

u.S. <strong>Fuel</strong> CyCle<br />

In countries like the United States where the reactor fleet is far from uniform and the burnup<br />

time and cooling time of the SNF inventory varies widely, the French commercial MOX<br />

strategy would be more difficult to implement for the current stock of SNF. If the U.S. is to<br />

achieve multi-objective fuel <strong>cycle</strong> goals, it is necessary to evaluate what is the preferred option<br />

that is applicable to the United States, for its current and future SNF inventory. In this<br />

context, there is a very large technical and economic difference between re<strong>cycle</strong> of most<br />

SNF and all SNF. If economics are a major component of a decision to re<strong>cycle</strong> SNF, the SNF<br />

with a high fissile assay will be re<strong>cycle</strong>d while SNF with a low fissile assay will be considered<br />

wastes. This is similar to the re<strong>cycle</strong> of metals, paper, and other waste streams worldwide.<br />

<strong>The</strong> last funded effort to address closing of the fuel <strong>cycle</strong> in the U.S. was led by the DOE<br />

Global Nuclear <strong>Energy</strong> Partnership (GNEP) program. It initially focused on R&D needs<br />

and small engineering-scale demonstration of advanced recycling technologies being developed<br />

as part of its R&D portfolio. Later, the GNEP strategy moved to deployment of<br />

full-scale commercial facilities which resulted in a Funding Opportunity Announcement<br />

to industry and funding of four cooperative agreements. 4 Industry provided deployment<br />

plans and conceptual designs for a <strong>nuclear</strong> fuel recycling center and an advanced recycling<br />

appendix e: Status of <strong>Fuel</strong> <strong>cycle</strong> Technologies 235