100th Annual Report 2006-2007 - Tata Steel

100th Annual Report 2006-2007 - Tata Steel

100th Annual Report 2006-2007 - Tata Steel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The “G” Blast Furnace in Jamshedpur crossed 2 million tonnes<br />

production of hot metal against its rated capacity of 1.8 million<br />

tonnes.<br />

The New Rebar Mill which was installed under the One million<br />

tonnes expansion project also achieved its rated capacity of<br />

50,000 tonne per month during the year. The total production<br />

of rebars at the Jamshedpur Works almost reached the 1 million<br />

tonne mark during the year.<br />

The Hot Strip Mill produced 3.24 million tonnes as compared<br />

to 3.08 million tonne in the previous year. The Cold Rolling Mill<br />

crossed the milestone of 1.5 million tonnes against its rated<br />

capacity of 1.2 million tonnes.<br />

The all round increase in production came with improvements<br />

in the manufacturing processes specially in the areas of specific<br />

consumption of raw materials, energy, refractories, water and lime.<br />

The Company successfully completed in-house up-gradation of<br />

the “E” blast furnace in Jamshedpur. The “E” blast furnace which<br />

used to produce 1,050 tonnes per day before up-gradation will<br />

now be able to produce 1,350 tonnes per day. The coke and<br />

fuel rate consumption of the “E” blast furnace will also reduce<br />

due to the increase in the size of the furnace.<br />

Raw Materials<br />

The West Bokaro Collieries for the first time dispatched 1.9<br />

million tonnes of clean coal at an average of 13% ash content.<br />

The reduced ash level in captive coal contributed significantly<br />

in substituting the more expensive imported low ash coal. In<br />

order to reduce the alumina content in the iron ore, a modern<br />

beneficiation plant for iron ore fines has been set up by<br />

the Company.<br />

Research & Development<br />

• Commercial production of various grades of high strength<br />

steel for automobiles was established for the first time.<br />

• Super ductile rebars and galvanised wires with thin organic<br />

coating were produced for the first time.<br />

• Breakthrough was achieved in establishing a new grade of<br />

cold rolled ultra low carbon electric grade steel which has<br />

significant usage in electrical appliances.<br />

G) Marketing & Sales<br />

Finished steel sales increased by 11.3% to 4.51 million tonnes<br />

as compared to 4.05 million tonnes in the previous year.<br />

Flat Products sales to the automotive sector were the highest<br />

ever at 0.86 million tonnes, an increase of 30% as compared<br />

to sales of 0.67 million tonnes in the previous year. Sales of<br />

specialty HR coils used for the long and cross members of chasis<br />

of heavy vehicles, high end cold rolled and coated sheets were<br />

also higher compared to last year.<br />

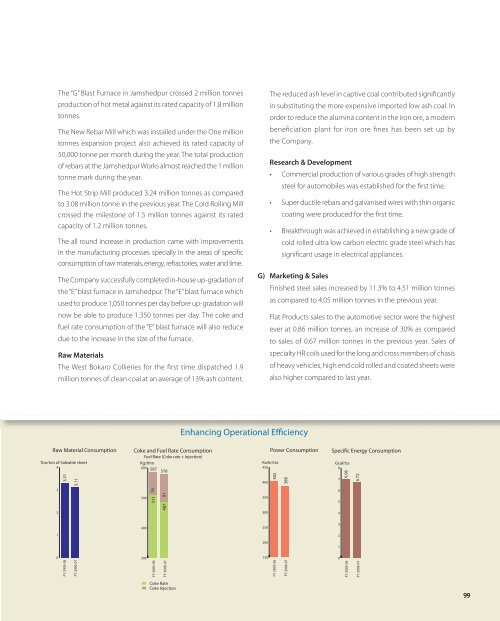

Enhancing Operational Efficiency<br />

Raw Material Consumption<br />

Ton/ton of Saleable sheet<br />

4<br />

3.31<br />

3.11<br />

Coke and Fuel Rate Consumption<br />

Fuel Rate (Coke rate + Injection)<br />

Kg/thm<br />

600 587 578<br />

Power Consumption<br />

Kwhr/tss<br />

450<br />

400<br />

402<br />

388<br />

Specific Energy Consumption<br />

Gcal/tss<br />

8<br />

7<br />

6.96<br />

6.72<br />

3<br />

76<br />

6<br />

500<br />

511<br />

91<br />

350<br />

5<br />

2<br />

487<br />

300<br />

4<br />

400<br />

250<br />

3<br />

1<br />

2<br />

200<br />

1<br />

0<br />

FY 2005-06<br />

FY <strong>2006</strong>-07<br />

300<br />

FY 2005-06<br />

FY <strong>2006</strong>-07<br />

150<br />

FY 2005-06<br />

FY <strong>2006</strong>-07<br />

0<br />

FY 2005-06<br />

FY <strong>2006</strong>-07<br />

Coke Rate<br />

Coke Injection<br />

99