Canadian Quality Milk On-Farm Food Safety Program - Centre ...

Canadian Quality Milk On-Farm Food Safety Program - Centre ...

Canadian Quality Milk On-Farm Food Safety Program - Centre ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Canadian</strong> <strong>Quality</strong> <strong>Milk</strong><br />

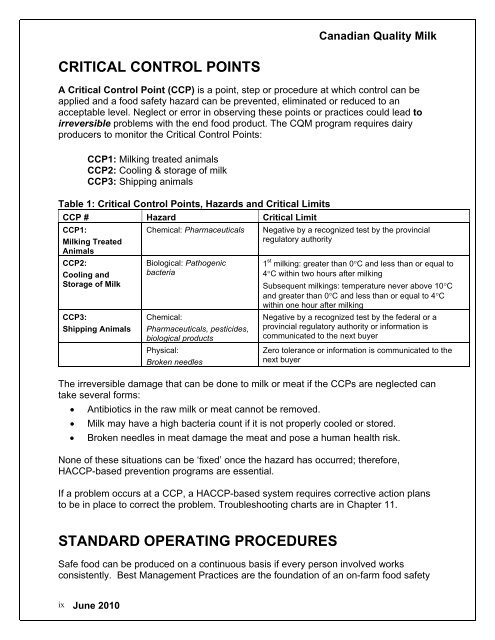

CRITICAL CONTROL POINTS<br />

A Critical Control Point (CCP) is a point, step or procedure at which control can be<br />

applied and a food safety hazard can be prevented, eliminated or reduced to an<br />

acceptable level. Neglect or error in observing these points or practices could lead to<br />

irreversible problems with the end food product. The CQM program requires dairy<br />

producers to monitor the Critical Control Points:<br />

CCP1: <strong>Milk</strong>ing treated animals<br />

CCP2: Cooling & storage of milk<br />

CCP3: Shipping animals<br />

Table 1: Critical Control Points, Hazards and Critical Limits<br />

CCP # Hazard Critical Limit<br />

CCP1:<br />

<strong>Milk</strong>ing Treated<br />

Animals<br />

CCP2:<br />

Cooling and<br />

Storage of <strong>Milk</strong><br />

CCP3:<br />

Shipping Animals<br />

Chemical: Pharmaceuticals<br />

Biological: Pathogenic<br />

bacteria<br />

Chemical:<br />

Pharmaceuticals, pesticides,<br />

biological products<br />

Physical:<br />

Broken needles<br />

Negative by a recognized test by the provincial<br />

regulatory authority<br />

1 st milking: greater than 0°C and less than or equal to<br />

4°C within two hours after milking<br />

Subsequent milkings: temperature never above 10°C<br />

and greater than 0°C and less than or equal to 4°C<br />

within one hour after milking<br />

Negative by a recognized test by the federal or a<br />

provincial regulatory authority or information is<br />

communicated to the next buyer<br />

Zero tolerance or information is communicated to the<br />

next buyer<br />

The irreversible damage that can be done to milk or meat if the CCPs are neglected can<br />

take several forms:<br />

• Antibiotics in the raw milk or meat cannot be removed.<br />

• <strong>Milk</strong> may have a high bacteria count if it is not properly cooled or stored.<br />

• Broken needles in meat damage the meat and pose a human health risk.<br />

None of these situations can be ‘fixed’ once the hazard has occurred; therefore,<br />

HACCP-based prevention programs are essential.<br />

If a problem occurs at a CCP, a HACCP-based system requires corrective action plans<br />

to be in place to correct the problem. Troubleshooting charts are in Chapter 11.<br />

STANDARD OPERATING PROCEDURES<br />

Safe food can be produced on a continuous basis if every person involved works<br />

consistently. Best Management Practices are the foundation of an on-farm food safety<br />

ix<br />

June 2010