Canadian Quality Milk On-Farm Food Safety Program - Centre ...

Canadian Quality Milk On-Farm Food Safety Program - Centre ...

Canadian Quality Milk On-Farm Food Safety Program - Centre ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Canadian</strong> <strong>Quality</strong> <strong>Milk</strong><br />

HAZARD ANALYSIS CRITICAL CONTROL POINT<br />

(HACCP) APPROACH<br />

A Hazard Analysis Critical Control Point Analysis (HACCP)-like approach is a<br />

systematic, science-based method of identifying and assessing food safety hazards in<br />

an operation and then developing steps to prevent, control and reduce those risks to<br />

acceptable levels.<br />

Advantages of a HACCP-based program are:<br />

• A consistent supply of safe milk and meat to<br />

processors and consumers.<br />

• Prevention of problems, which is cheaper than solving<br />

problems.<br />

• Reduced penalties and less raw and finished product<br />

wastage.<br />

• Increased industry and consumer confidence.<br />

• Better mechanism to respond to consumer demand for<br />

food safety.<br />

• Increased producer and processor milk and meat<br />

production efficiencies and improvements.<br />

• Better control over management = lower production<br />

costs = higher producer profits.<br />

• Standardization of daily routines.<br />

• Improved herd health.<br />

• Reduced environmental impact.<br />

• Increased producer gains from quality incentive payments (where applicable).<br />

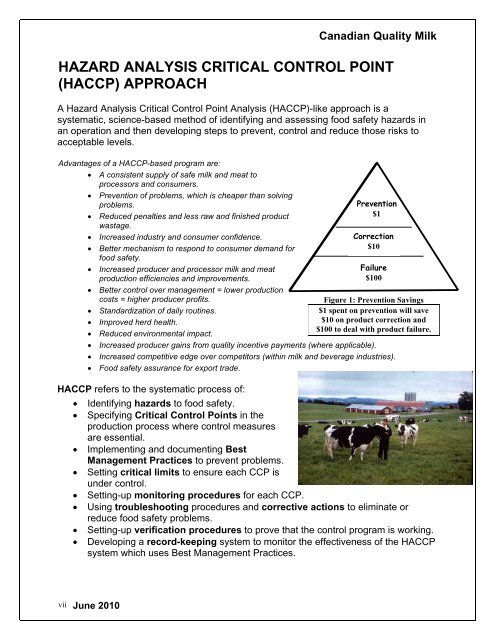

Prevention<br />

$1<br />

Correction<br />

$10<br />

Failure<br />

$100<br />

Figure 1: Prevention Savings<br />

$1 spent on prevention will save<br />

$10 on product correction and<br />

$100 to deal with product failure.<br />

• Increased competitive edge over competitors (within milk and beverage industries).<br />

• <strong>Food</strong> safety assurance for export trade.<br />

HACCP refers to the systematic process of:<br />

• Identifying hazards to food safety.<br />

• Specifying Critical Control Points in the<br />

production process where control measures<br />

are essential.<br />

• Implementing and documenting Best<br />

Management Practices to prevent problems.<br />

• Setting critical limits to ensure each CCP is<br />

under control.<br />

• Setting-up monitoring procedures for each CCP.<br />

• Using troubleshooting procedures and corrective actions to eliminate or<br />

reduce food safety problems.<br />

• Setting-up verification procedures to prove that the control program is working.<br />

• Developing a record-keeping system to monitor the effectiveness of the HACCP<br />

system which uses Best Management Practices.<br />

vii<br />

June 2010