Yearbook 2013/2014 - ehedg

Yearbook 2013/2014 - ehedg

Yearbook 2013/2014 - ehedg

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

European Hygienic Engineering & Design Group<br />

Modern level detection and measurement technologies<br />

Sticky media, foam, changing media and hygienic installation present challenges for fill level<br />

detection and measurement. In order to improve reliability and reduce the downtime of machinery<br />

it is crucial that a level sensor switches off when the tank, vessel or tube is empty, even if the tip<br />

is still covered with the medium. Any medium that produces foam is especially tricky because<br />

an overflow protection has to detect it, whereas a level measurement and an empty detection<br />

should mask the foam. A modern level measurement and detection should also work even if the<br />

medium changes. This article gives a guideline of technologies to solve these challenges, as<br />

well as some information on hygienic mounting.<br />

Daniel Walldorf, Baumer GmbH, Friedberg, Germany, dwalldorf@baumer.com, www.baumer.com<br />

Frequency sweep technology<br />

for level switches<br />

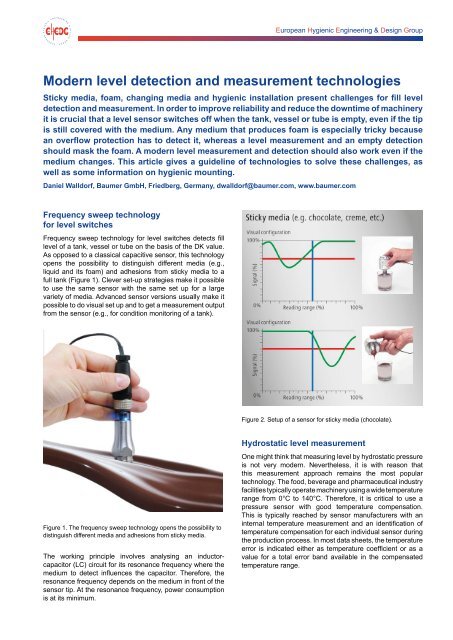

Frequency sweep technology for level switches detects fill<br />

level of a tank, vessel or tube on the basis of the DK value.<br />

As opposed to a classical capacitive sensor, this technology<br />

opens the possibility to distinguish different media (e.g.,<br />

liquid and its foam) and adhesions from sticky media to a<br />

full tank (Figure 1). Clever set-up strategies make it possible<br />

to use the same sensor with the same set up for a large<br />

variety of media. Advanced sensor versions usually make it<br />

possible to do visual set up and to get a measurement output<br />

from the sensor (e.g., for condition monitoring of a tank).<br />

Figure 2. Setup of a sensor for sticky media (chocolate).<br />

Figure 1. The frequency sweep technology opens the possibility to<br />

distinguish different media and adhesions from sticky media.<br />

The working principle involves analysing an inductorcapacitor<br />

(LC) circuit for its resonance frequency where the<br />

medium to detect influences the capacitor. Therefore, the<br />

resonance frequency depends on the medium in front of the<br />

sensor tip. At the resonance frequency, power consumption<br />

is at its minimum.<br />

Hydrostatic level measurement<br />

One might think that measuring level by hydrostatic pressure<br />

is not very modern. Nevertheless, it is with reason that<br />

this measurement approach remains the most popular<br />

technology. The food, beverage and pharmaceutical industry<br />

facilities typically operate machinery using a wide temperature<br />

range from 0°C to 140°C. Therefore, it is critical to use a<br />

pressure sensor with good temperature compensation.<br />

This is typically reached by sensor manufacturers with an<br />

internal temperature measurement and an identification of<br />

temperature compensation for each individual sensor during<br />

the production process. In most data sheets, the temperature<br />

error is indicated either as temperature coefficient or as a<br />

value for a total error band available in the compensated<br />

temperature range.