1. magnetic confinement - ENEA - Fusione

1. magnetic confinement - ENEA - Fusione

1. magnetic confinement - ENEA - Fusione

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

84<br />

3. FUSION TECHNOLOGY<br />

3.7 Materials<br />

(liquid metal velocity 0.5-1 m/s). The aim is to quantify<br />

eventual degradation of the mechanical and elastic<br />

properties of the composite because of corrosion, with the<br />

use of nondestructive techniques including geometrical<br />

dimensions, mass variation, longitudinal and torsional<br />

dynamic moduli of elasticity (by the longitudinal and<br />

torsional fundamental resonant frequency method).<br />

The materials to be investigated include CERASEP N31, N41<br />

and <strong>ENEA</strong> PIP composites.<br />

The upgrading of the LIFUS2 facility at <strong>ENEA</strong> Brasimone to<br />

increase the exposure temperature to 550°C was completed.<br />

The exposure phase was completed for 100 and 1000 h. The<br />

characterisation of the samples exposed for 100 h showed the<br />

absence of erosion-corrosion phenomena but the presence of<br />

consistent liquid infiltration (fig. 3.20). The characterisation of the samples exposed<br />

for 1000 and 6000 h is ongoing.<br />

3.7.2 Microstructural investigation of radiation effects in RAFM<br />

steel by SANS<br />

These activities are carried out in collaboration with FZK. Small-angle neutron<br />

scattering (SANS) measurements were performed at the High Flux Reactor of ILL-<br />

Grenoble. An automatic sample changer designed for handling highly activated<br />

material (up to 1 Sv at 10 cm) was developed. OPTIFER (I and V) and F82H steels,<br />

neutron irradiated at 250-450°C with 2.8 dpa, with and without post-irradiation<br />

annealing at 525 and 700°C, were investigated. Non-irradiated oxide dispersion<br />

strengthened (ODS) EUROFER97 samples (up to 0.5% Y 2 O 3 ) were also examined.<br />

Under 2.8 dpa irradiation, the SANS cross section increases remarkably compared to<br />

the non-irradiated samples, which reflects the presence of defects, such as He<br />

bubbles. The ratio nuclear +<br />

<strong>magnetic</strong>/nuclear scattering changes<br />

significantly under irradiation, which<br />

is a sign of changes in precipitate<br />

composition. The difference between<br />

the irradiated and reference<br />

samples appears to be independent<br />

of the orientation relative to<br />

the applied <strong>magnetic</strong> field in the postirradiated<br />

35.0<br />

28.0<br />

2<strong>1.</strong>0<br />

heat-treated specimens.<br />

This can be attributed to the 14.0<br />

growth of He bubbles. Figure 3.21<br />

shows a comparison of oxide 7.0<br />

particle distributions obtained by<br />

transmission electron microscopy 0.0<br />

(TEM) and SANS for the EUROFER97<br />

0.0 7.0 14.0 2<strong>1.</strong>0 28.0 35.0<br />

ODS samples.<br />

d (nm)<br />

Rel. frequency<br />

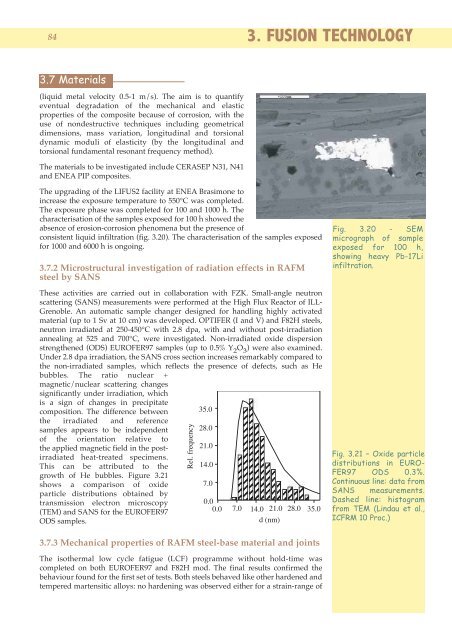

Fig. 3.20 - SEM<br />

micrograph of sample<br />

exposed for 100 h,<br />

showing heavy Pb-17Li<br />

infiltration.<br />

Fig. 3.21 – Oxide particle<br />

distributions in EURO-<br />

FER97 ODS 0.3%.<br />

Continuous line: data from<br />

SANS measurements.<br />

Dashed line: histogram<br />

from TEM (Lindau et al.,<br />

ICFRM 10 Proc.)<br />

3.7.3 Mechanical properties of RAFM steel-base material and joints<br />

The isothermal low cycle fatigue (LCF) programme without hold-time was<br />

completed on both EUROFER97 and F82H mod. The final results confirmed the<br />

behaviour found for the first set of tests. Both steels behaved like other hardened and<br />

tempered martensitic alloys: no hardening was observed either for a strain-range of