MICROMASTER 440 - Siemens AS

MICROMASTER 440 - Siemens AS

MICROMASTER 440 - Siemens AS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Issue 10/06<br />

6 Commissioning<br />

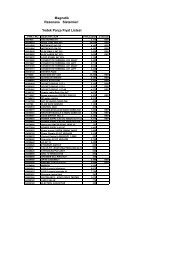

6.4.18.8 Load torque monitoring<br />

This function monitors the transmission of force between a motor and driven load<br />

within a defined frequency range. Typical applications include, for example,<br />

detecting when a transmission belt breaks or detecting when a conveyor belt is in<br />

an overload condition.<br />

For the load torque monitoring, the actual frequency/torque actual value is<br />

compared to a programmed frequency/torque characteristic (refer to P2182 –<br />

P2190). Depending on P2181, the system monitors whether the permissible torque<br />

curve is either exceeded or fallen below. If the actual value lies outside the<br />

tolerance bandwidth, then after the delay time P2192 has expired, either alarm<br />

A0952 is output or fault F0452.<br />

P2181 = ...<br />

P2182 = ...<br />

P2183 = ...<br />

P2184 = ...<br />

P2185 = ...<br />

P2186 = ...<br />

P2187 = ...<br />

P2188 = ...<br />

P2189 = ...<br />

P2190 = ...<br />

P2192 = ...<br />

Belt failure detection mode<br />

Parameter P2181 activates or de-activates the load torque monitoring and defines the<br />

response to a load torque fault.<br />

0 Belt failure detection disabled<br />

1 Warning: Low torque / frequency<br />

2 Warning: High torque / frequency<br />

3 Warning: High / low torque / frequency<br />

4 Trip: Low torque / frequency<br />

5 Trip: High torque / frequency<br />

6 Trip: High / low torque / frequency<br />

Belt threshold frequency 1<br />

5.00<br />

Sets a frequency threshold 1 for comparing actual torque to torque the envelope for belt<br />

failure detection.<br />

Belt threshold frequency 2<br />

30.00<br />

Sets a frequency threshold 2.<br />

Belt threshold frequency 3<br />

50.00<br />

Sets a frequency threshold 3.<br />

Upper torque threshold 1<br />

99999.0<br />

Upper limit threshold value 1 for comparing actual torque.<br />

Lower torque threshold 1<br />

0.0<br />

Lower limit threshold value 1 for comparing actual torque.<br />

Upper torque threshold 2<br />

99999.0<br />

Upper limit threshold value 2 for comparing actual torque.<br />

Lower torque threshold 2<br />

0.0<br />

Lower limit threshold value 2 for comparing actual torque.<br />

Upper torque threshold 3<br />

99999.0<br />

Upper limit threshold value 3 for comparing actual torque.<br />

Lower torque threshold 3<br />

0.0<br />

Lower limit threshold value 3 for comparing actual torque.<br />

Time delay for belt failure<br />

10<br />

P2192 defines a delay before warning/trip becomes active. It is used to eliminate events<br />

caused by transient conditions. It is used for both methods of fault detection.<br />

<strong>MICROM<strong>AS</strong>TER</strong> <strong>440</strong><br />

Operating Instructions (Compact) 61