Radio Broadcast - 1925, February - 113 Pages ... - VacuumTubeEra

Radio Broadcast - 1925, February - 113 Pages ... - VacuumTubeEra

Radio Broadcast - 1925, February - 113 Pages ... - VacuumTubeEra

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

i Cut<br />

I<br />

1<br />

712 <strong>Radio</strong> <strong>Broadcast</strong><br />

template and ream out the holes in the fibre<br />

with the No. 19 drill.<br />

a strip of tin as shown in the sketch<br />

Fig. 2 and bolt it to the center of one of the<br />

fibre circles. Mark the spokes with it using<br />

a scratch awl and not a pencil, then cut on<br />

these lines with the tin snips and you will have<br />

a perfectly good form. Sec Fig. 3.<br />

The forms should be boiled in paraffin for<br />

about ten minutes before winding or they<br />

will absorb moisture. After they are wound,<br />

the coils may be painted with a thin solution<br />

of celluloid dissolved in acetone. HARDING<br />

Cow, East Sound, Wash.<br />

IN<br />

A FILTER FOR THE<br />

SUPER-HETERODYNE<br />

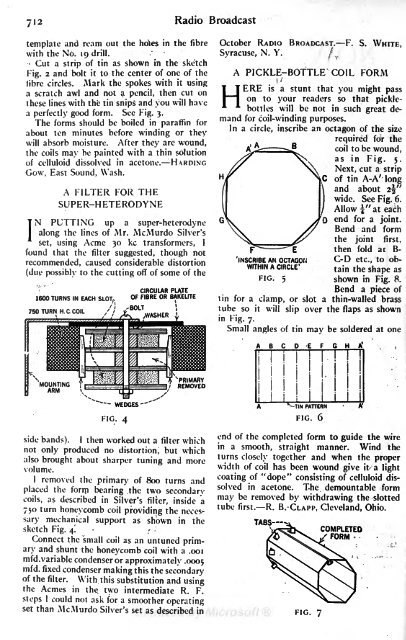

PUTTING up a super-heterodyne<br />

along the lines of Mr. McMurdo Silver's<br />

set, using Acme 30 kc transformers, 1<br />

found that the filter suggested, though not<br />

recommended, caused considerable distortion<br />

(due possibly to the cutting off of some of the<br />

CIRCULAR PLATE<br />

1600 TURNS IN EACH SLOT. OF FIBRE OR BAKELITE<br />

f\ \<br />

750 TURN H.CCOIL<br />

October RADIO BROADCAST. F. S. WHITE,<br />

Syracuse, N. Y.<br />

A PICKLE-BOTTLE COIL<br />

B<br />

FORM<br />

HERE is a stunt that you might pass<br />

on to your readers so that picklebottles<br />

will be not in such great demand<br />

for coil-winding purposes.<br />

In a circle, inscribe an octagon of the size<br />

H<br />

'INSCRIBE AN OCTAGON<br />

WITHIN A CIRCLE'<br />

FIG.<br />

S<br />

required for the<br />

coil to be wound,<br />

as in Fig. 5 .<br />

Next, cut a strip<br />

C of tin A-A' long<br />

\ and about 2f"<br />

I<br />

wide. See Fig. 6.<br />

Allow \" at each<br />

end for a joint.<br />

Bend and form<br />

the joint first,<br />

then fold ac B-<br />

C-D etc., to obtain<br />

the shape as<br />

shown in Fig. 8.<br />

Bend a piece of<br />

tin for a clamp, or slot a thin-walled brass<br />

tube so it will slip over the flaps as shown<br />

in Fig. 7.<br />

Small angles of tin<br />

may<br />

be soldered at one<br />

A B C D E F G H A*<br />

FIG. 4<br />

side bands).<br />

I then worked out a filter which<br />

not only produced no distortion, but which<br />

also brought about sharper tuning and more<br />

volume.<br />

I removed the primary of 800 turns and<br />

placed the form bearing the two secondary<br />

coils, as described in Silver's filter, inside a<br />

750 turn honeycomb coil providing the necessary<br />

mechanical support as shown in the<br />

sketch Fig. 4.<br />

Connect the small coil as an untuned primary<br />

and shunt the honeycomb coil with a .001<br />

mfd. variable condenser or approximately .0005<br />

mfd. fixed condenser making this the secondary<br />

of the filter. With this substitution and using<br />

the Acmes in the two intermediate R. F.<br />

steps I<br />

could not ask for a smoother operating<br />

set than McMurdo Silver's set as described in