chapter - 1 introduction - Meghalaya State Pollution Control Board

chapter - 1 introduction - Meghalaya State Pollution Control Board

chapter - 1 introduction - Meghalaya State Pollution Control Board

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Hills Cement Co. Limited.<br />

6.1. RAW MATERIALS PREPARATION<br />

1. Efficient Transport Systems (Dry Process) - Transport systems are<br />

required to convey powdered materials such as kiln feed, kiln dust,<br />

and finished cement throughout the plant. Mechanical conveyors use<br />

less power than pneumatic systems & the average energy savings are<br />

estimated at 2.0-kWh/tonne raw materials with a switch to mechanical<br />

conveyor systems. Conversion to mechanical conveyors is costeffective<br />

when replacement of conveyor systems is needed to<br />

increase reliability and reduce downtime.<br />

2. Use of roller mills (Dry Process)- Traditional ball mills used for grinding<br />

certain raw materials (mainly hard limestone) can be replaced by highefficiency<br />

roller mills, by ball mills combined with high-pressure roller<br />

presses, or by horizontal roller mills. The use of these advanced mills<br />

saves energy without compromising product quality.<br />

3. High-efficiency classifiers/separators- A recent development in<br />

efficient grinding technologies is the use of high-efficiency classifiers<br />

or separators. Classifiers separate the finely ground particles from the<br />

coarse particles. The large particles are then recycled back to the mill.<br />

<strong>Pollution</strong> <strong>Control</strong> Consultants (India) Pvt. Ltd. 116

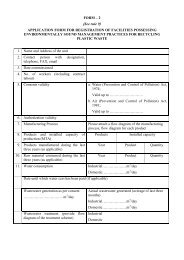

![[FORM I] - Meghalaya State Pollution Control Board](https://img.yumpu.com/49771786/1/190x245/form-i-meghalaya-state-pollution-control-board.jpg?quality=85)