chapter - 1 introduction - Meghalaya State Pollution Control Board

chapter - 1 introduction - Meghalaya State Pollution Control Board

chapter - 1 introduction - Meghalaya State Pollution Control Board

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Hills Cement Co. Limited.<br />

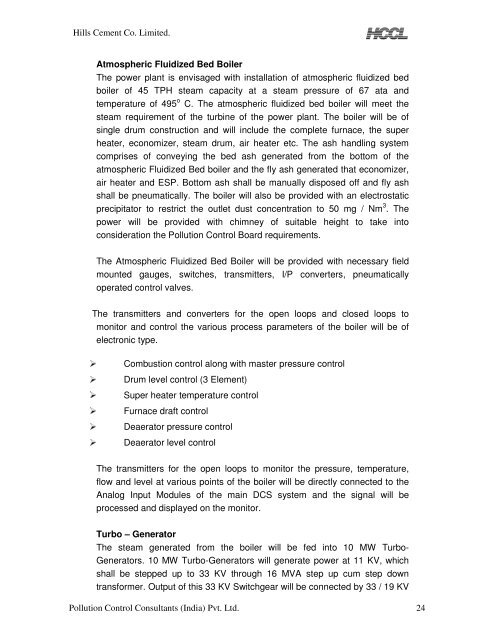

Atmospheric Fluidized Bed Boiler<br />

The power plant is envisaged with installation of atmospheric fluidized bed<br />

boiler of 45 TPH steam capacity at a steam pressure of 67 ata and<br />

temperature of 495 o C. The atmospheric fluidized bed boiler will meet the<br />

steam requirement of the turbine of the power plant. The boiler will be of<br />

single drum construction and will include the complete furnace, the super<br />

heater, economizer, steam drum, air heater etc. The ash handling system<br />

comprises of conveying the bed ash generated from the bottom of the<br />

atmospheric Fluidized Bed boiler and the fly ash generated that economizer,<br />

air heater and ESP. Bottom ash shall be manually disposed off and fly ash<br />

shall be pneumatically. The boiler will also be provided with an electrostatic<br />

precipitator to restrict the outlet dust concentration to 50 mg / Nm 3 . The<br />

power will be provided with chimney of suitable height to take into<br />

consideration the <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong> requirements.<br />

The Atmospheric Fluidized Bed Boiler will be provided with necessary field<br />

mounted gauges, switches, transmitters, I/P converters, pneumatically<br />

operated control valves.<br />

The transmitters and converters for the open loops and closed loops to<br />

monitor and control the various process parameters of the boiler will be of<br />

electronic type.<br />

¾<br />

¾<br />

¾<br />

¾<br />

¾<br />

¾<br />

Combustion control along with master pressure control<br />

Drum level control (3 Element)<br />

Super heater temperature control<br />

Furnace draft control<br />

Deaerator pressure control<br />

Deaerator level control<br />

The transmitters for the open loops to monitor the pressure, temperature,<br />

flow and level at various points of the boiler will be directly connected to the<br />

Analog Input Modules of the main DCS system and the signal will be<br />

processed and displayed on the monitor.<br />

Turbo – Generator<br />

The steam generated from the boiler will be fed into 10 MW Turbo-<br />

Generators. 10 MW Turbo-Generators will generate power at 11 KV, which<br />

shall be stepped up to 33 KV through 16 MVA step up cum step down<br />

transformer. Output of this 33 KV Switchgear will be connected by 33 / 19 KV<br />

<strong>Pollution</strong> <strong>Control</strong> Consultants (India) Pvt. Ltd. 24

![[FORM I] - Meghalaya State Pollution Control Board](https://img.yumpu.com/49771786/1/190x245/form-i-meghalaya-state-pollution-control-board.jpg?quality=85)