chapter - 1 introduction - Meghalaya State Pollution Control Board

chapter - 1 introduction - Meghalaya State Pollution Control Board

chapter - 1 introduction - Meghalaya State Pollution Control Board

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

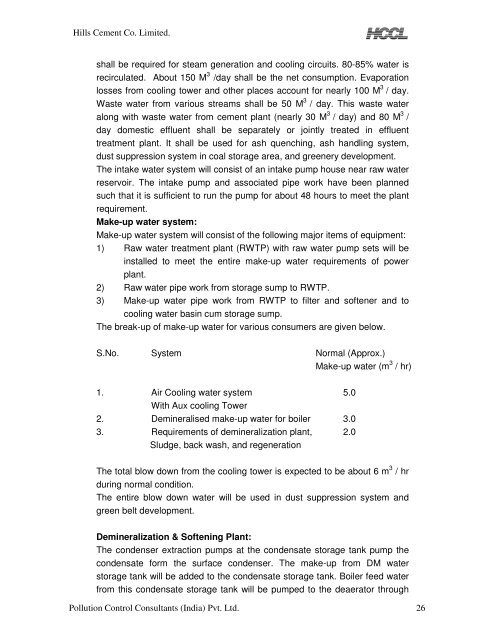

Hills Cement Co. Limited.<br />

shall be required for steam generation and cooling circuits. 80-85% water is<br />

recirculated. About 150 M 3 /day shall be the net consumption. Evaporation<br />

losses from cooling tower and other places account for nearly 100 M 3 / day.<br />

Waste water from various streams shall be 50 M 3 / day. This waste water<br />

along with waste water from cement plant (nearly 30 M 3 / day) and 80 M 3 /<br />

day domestic effluent shall be separately or jointly treated in effluent<br />

treatment plant. It shall be used for ash quenching, ash handling system,<br />

dust suppression system in coal storage area, and greenery development.<br />

The intake water system will consist of an intake pump house near raw water<br />

reservoir. The intake pump and associated pipe work have been planned<br />

such that it is sufficient to run the pump for about 48 hours to meet the plant<br />

requirement.<br />

Make-up water system:<br />

Make-up water system will consist of the following major items of equipment:<br />

1) Raw water treatment plant (RWTP) with raw water pump sets will be<br />

installed to meet the entire make-up water requirements of power<br />

plant.<br />

2) Raw water pipe work from storage sump to RWTP.<br />

3) Make-up water pipe work from RWTP to filter and softener and to<br />

cooling water basin cum storage sump.<br />

The break-up of make-up water for various consumers are given below.<br />

S.No. System Normal (Approx.)<br />

Make-up water (m 3 / hr)<br />

1. Air Cooling water system 5.0<br />

With Aux cooling Tower<br />

2. Demineralised make-up water for boiler 3.0<br />

3. Requirements of demineralization plant, 2.0<br />

Sludge, back wash, and regeneration<br />

The total blow down from the cooling tower is expected to be about 6 m 3 / hr<br />

during normal condition.<br />

The entire blow down water will be used in dust suppression system and<br />

green belt development.<br />

Demineralization & Softening Plant:<br />

The condenser extraction pumps at the condensate storage tank pump the<br />

condensate form the surface condenser. The make-up from DM water<br />

storage tank will be added to the condensate storage tank. Boiler feed water<br />

from this condensate storage tank will be pumped to the deaerator through<br />

<strong>Pollution</strong> <strong>Control</strong> Consultants (India) Pvt. Ltd. 26

![[FORM I] - Meghalaya State Pollution Control Board](https://img.yumpu.com/49771786/1/190x245/form-i-meghalaya-state-pollution-control-board.jpg?quality=85)