chapter - 1 introduction - Meghalaya State Pollution Control Board

chapter - 1 introduction - Meghalaya State Pollution Control Board

chapter - 1 introduction - Meghalaya State Pollution Control Board

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Hills Cement Co. Limited.<br />

XLPE insulated aluminum conductor screened & armored cable directly to 33<br />

KV bus of the Substation.<br />

The concept of the instrumentation system for the TG will also be similar to<br />

that of traveling grate boiler. DCS will be provided for the following closed<br />

loop controls:<br />

¾ Hot well level control<br />

¾ Gland steam pressure control<br />

¾ Pressure and temperature control<br />

The transmitters for the open loops of TG will also be wired to the main DCS<br />

system. The protection and interlocking system of the turbine will also be<br />

performed by the main DCS by connecting the field-mounted switches to the<br />

DCS system.<br />

The turbine will also be provided with the surface condenser, condensate<br />

extraction pumps, and gland vent condenser. Governing system of the<br />

turbine will be by electro hydraulic type to govern the turbine speed during<br />

varying load demands the fluctuations. The speed governing system will limit<br />

the over speed of the TG set on loss of full load to avoid tripping by the over<br />

speed device.<br />

The instrumentation and control system for the Atmospheric Fluidized Bed<br />

Boiler and the turbo generator unit, etc., will be of electronic instruments with<br />

pneumatic final control elements using the latest state of art of technology<br />

viz., DCS system along with PC based automation system for monitoring and<br />

control of the power plants from the control room. All the necessary<br />

instruments required for proper operation of the plants will be provided.<br />

The CPP is proposed to be operated in synchronous mode with <strong>Meghalaya</strong><br />

<strong>State</strong> Grid. The generated electrical power will be consumed in-house for the<br />

existing cement plant and CPP auxiliaries’ power. The plant utility<br />

requirements like compressed air, instrument air, water, etc., are all suitably<br />

designed to meet the power plant requirement. The capacities of the<br />

equipments used in this system have been considered with sufficient margins<br />

to take care of these requirements.<br />

WATER REQUIREMENT<br />

Apart from steam generation, water is used as a cooling medium in the heat<br />

exchanger equipments in power plant such as condensers, oil coolers,<br />

generator air coolers etc. of turbo generator. Nearly 1,100 M 3 / day water<br />

<strong>Pollution</strong> <strong>Control</strong> Consultants (India) Pvt. Ltd. 25

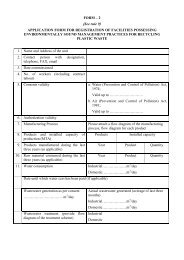

![[FORM I] - Meghalaya State Pollution Control Board](https://img.yumpu.com/49771786/1/190x245/form-i-meghalaya-state-pollution-control-board.jpg?quality=85)