chapter - 1 introduction - Meghalaya State Pollution Control Board

chapter - 1 introduction - Meghalaya State Pollution Control Board

chapter - 1 introduction - Meghalaya State Pollution Control Board

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Hills Cement Co. Limited.<br />

transfer pumps with standby facility. The level inside the deaerated feed<br />

water storage tank shall be maintained at constant set valves by controlling<br />

the quantum of feed pumped by the transfer pumps.<br />

The deaerated feed water from the feed water storage tank will be supplied<br />

to the steam generator by means of boiler feed water pumps of adequate<br />

capacity to cater the requirements of 45 TPH Boiler. To cater the make-up<br />

water requirement of the steam generation/turbine cycle, a demineralization<br />

water plant having capacity of 4 cum / hr is proposed.<br />

COMPRESSED AIR SYSTEM<br />

To cater the requirement of the compressed air for instruments and the<br />

control systems two compressors rated for 100 N.Cu.M/hr at 8.0 Kg/Cm 2<br />

shall be installed. The air compressor shall be provided with accessories like<br />

inter cooler, moisture separators, air dryers, air receivers, and control panel.<br />

Two stage reciprocating air compressors shall be belt driven, oil free, nonlubricating<br />

type. The design of the reciprocating compressor shall be in<br />

accordance with API 618. The rotating parts shall be dynamically balanced<br />

according to the standard to minimize noise and vibrations.<br />

VENTILATION AND AIR CONDITIONING SYSTEM<br />

Air-conditioning systems, where required with suitable natural as well as<br />

mechanical ventilation be proved for various plant areas. Filtered air supply<br />

and exhaust arrangements shall be provided for MCC rooms and switchgear<br />

rooms. The rooms shall be kept under positive pressure of +5 mm by means<br />

of gravity louvers. Necessary roof extractors will be provided in the machine<br />

bay to ensure at least ten (10) number of air change.<br />

DC Power supply System<br />

The essential loads within the power plant which are too maintained during<br />

an emergency situation are listed below:<br />

Emergency lube oil pump<br />

¾<br />

¾<br />

Emergency lighting<br />

<strong>Control</strong> power supply to various switchboards, electrical control panels<br />

of 11 kV.<br />

Annunciation system<br />

In order to meet the above requirement at 110 V DC, Maintenance free lead<br />

acid battery bank of adequate capacity along with charger unit will be<br />

provided. The battery capacity will be designed based on 30 min supply to<br />

the essential auxiliaries and one-hour duration for emergency lighting<br />

<strong>Pollution</strong> <strong>Control</strong> Consultants (India) Pvt. Ltd. 27

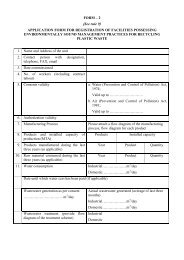

![[FORM I] - Meghalaya State Pollution Control Board](https://img.yumpu.com/49771786/1/190x245/form-i-meghalaya-state-pollution-control-board.jpg?quality=85)