tal leadership by maintaining the performance of more than ... - Toyota

tal leadership by maintaining the performance of more than ... - Toyota

tal leadership by maintaining the performance of more than ... - Toyota

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Health and Safety<br />

Steve Hope<br />

General Manager Plant Engineering<br />

& Safety<br />

Erik Van de Wiele<br />

Director Business Services<br />

Overall 2010 European winning entry from TMMP<br />

Led <strong>by</strong> our top management, <strong>the</strong> fi rst children’s safety<br />

drawing competition was held in FY10. The competition – to<br />

create a drawing based on <strong>the</strong> <strong>the</strong>me <strong>of</strong> safety at home, at<br />

school, crossing <strong>the</strong> road or parents at work, was open to<br />

children <strong>of</strong> <strong>Toyota</strong> members. This created <strong>the</strong> opportunity for<br />

debate on safety within <strong>the</strong> family. A to<strong>tal</strong> <strong>of</strong> 189 entries from<br />

children across Europe were received.<br />

Health and Safety at Production Sites<br />

Our single event LTI rate has increased. Careful in depth<br />

analysis revealed that much <strong>of</strong> this increase is due to <strong>the</strong><br />

need to be reactive and <strong>the</strong> diffi culty <strong>of</strong> identifying hazards<br />

when confronted with rapid and frequent changes in our<br />

production environment.<br />

Considerable work has been undertaken to minimise this<br />

increase, including reinforcing <strong>the</strong> importance <strong>of</strong> planning<br />

and proactive safety management as well as encouraging<br />

active involvement <strong>of</strong> all our stakeholders. STAR (Stop Think<br />

Act Review) is a pocket-sized guidebook introduced at TMUK<br />

and used in <strong>the</strong> production environment to help members<br />

identify hazards when preparing for new or unusual tasks.<br />

This initiative has now been shared with o<strong>the</strong>r plants.<br />

(1) No comparable automative manufacturing industry benchmark data could be found <strong>by</strong> TME.<br />

The changing economic environment has<br />

presented <strong>Toyota</strong> with many challenges for<br />

safety management throughout our operations<br />

over <strong>the</strong> past year. We have not only taken on<br />

<strong>the</strong>se challenges but also continued to improve<br />

our core safety management activity.<br />

<strong>Toyota</strong> is fully committed to achieve and maintain<br />

a safe and healthy working environment for all its<br />

members. The <strong>of</strong>fi ce and workshop ergonomics<br />

project, organised <strong>by</strong> <strong>the</strong> Health & Safety team<br />

demonstrates this commitment.<br />

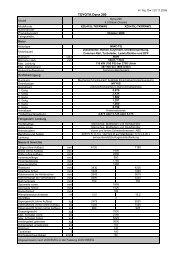

Manufacturing LTIs to FY10 (1)<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

0.0<br />

2.7<br />

3.0<br />

FY 06 07 08 09 10<br />

Single event Ergonomic (Cumulative) injury<br />

Lost time injury frequency rate (based on one or <strong>more</strong> days lost)<br />

in European manufacturing.<br />

Lost time injury frequency rate = No <strong>of</strong> LTI/ No <strong>of</strong> work hours x1,000,000,<br />

TPCA was included for <strong>the</strong> first time in FY07.<br />

During our annual summer shutdown a large number <strong>of</strong><br />

contractors come to <strong>Toyota</strong> plants to support planned<br />

maintenance. Such a high level <strong>of</strong> activity at one time can<br />

present many safety challenges. To recognise special effort and<br />

to encourage safety kaizen, TMMF introduced a “Safety Trophy”<br />

award system. Throughout <strong>the</strong> shutdown, contractors were<br />

evaluated on a daily basis to fi nd <strong>the</strong> best examples <strong>of</strong> proactive<br />

safety management and work area tidiness. From <strong>the</strong> daily<br />

winners an overall winner was selected and a special presentation<br />

was made in September <strong>by</strong> TMMF senior management.<br />

Presentation <strong>by</strong> TMMF top management to winning<br />

companies, including <strong>the</strong> winner Branson<br />

0.4<br />

2.6<br />

0.5<br />

1.6<br />

0.5<br />

2.8<br />

<strong>Toyota</strong> European Sustainability Report 2011 I Social Performance<br />

51