- Page 2 and 3:

EXECUTIVE SUMMARYTM

- Page 4 and 5:

Executive SummaryA summary of the p

- Page 6 and 7:

Executive SummaryIdentification of

- Page 8 and 9:

TABLE OF CONTENTSTM

- Page 10 and 11: Table of Contents2.4.5.2 Boot Lake

- Page 13 and 14: Table of Contents6.2.4 Birds ......

- Page 15 and 16: Table of Contents9.1.3 Environmenta

- Page 17 and 18: Table of Contents6.2-4 Species of F

- Page 19 and 20: 1. INTRODUCTIONTM

- Page 21 and 22: Ellice RiverAI No. a16725f-EISJob N

- Page 23 and 24: Introduction• Working with the ap

- Page 25 and 26: IntroductionTable 1.3-1Major Permit

- Page 27: IntroductionThe Project does not in

- Page 30 and 31: 2. Project Description2.1 Project L

- Page 32 and 33: gis no. 833-2-05 Job No. 833-2 Dece

- Page 34 and 35: Project Description2.1.3 Project Ne

- Page 36 and 37: Project Description2.4 Mine Plan2.4

- Page 38 and 39: Project DescriptionThe Upper Rhyoli

- Page 40 and 41: Project DescriptionA portion of the

- Page 42 and 43: Project Descriptionthe first phase

- Page 44 and 45: Project Description2.4.5.2 Boot Lak

- Page 46 and 47: Project Descriptionaccessories and

- Page 48 and 49: Project Descriptionneutralizing cal

- Page 50 and 51: Project Descriptionprefeasibility s

- Page 52 and 53: Project Description2.5.4 Zinc Flota

- Page 54 and 55: Project Description2.6.1.5 Site Pow

- Page 56 and 57: Project DescriptionThe electrical r

- Page 58 and 59: Project DescriptionThe airstrip wil

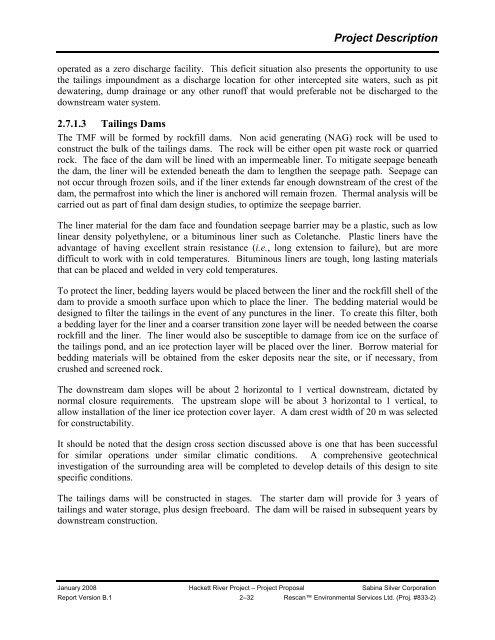

- Page 62 and 63: Project Description2.7.1.4 ClosureC

- Page 64 and 65: Project DescriptionDrainage from op

- Page 66 and 67: Project Descriptionmultiple-culvert

- Page 68 and 69: Project Description2.8.3.1 Location

- Page 70 and 71: Project DescriptionTypical bridge d

- Page 72 and 73: Project Description2.8.4 Overland T

- Page 74 and 75: Project Description• Desalination

- Page 76 and 77: Project Description2.9.5.2 Water Co

- Page 78 and 79: Project Descriptionrequire bridge c

- Page 80 and 81: 3. Training and Employment3.1 Human

- Page 82 and 83: Training and Employment3.5 Workforc

- Page 84 and 85: 4. Description of Public Involvemen

- Page 86 and 87: Description of Public Involvement a

- Page 88 and 89: Description of Public Involvement a

- Page 90 and 91: 5. Description of Traditional Knowl

- Page 92 and 93: 6. DESCRIPTION OF THE EXISTING ENVI

- Page 94 and 95: Description of the Existing Environ

- Page 96 and 97: Description of the Existing Environ

- Page 98 and 99: Description of the Existing Environ

- Page 100 and 101: Description of the Existing Environ

- Page 102 and 103: Description of the Existing Environ

- Page 104 and 105: Description of the Existing Environ

- Page 106 and 107: Description of the Existing Environ

- Page 109 and 110: Description of the Existing Environ

- Page 111 and 112:

Description of the Existing Environ

- Page 113 and 114:

Description of the Existing Environ

- Page 115 and 116:

Description of the Existing Environ

- Page 117 and 118:

Description of the Existing Environ

- Page 119 and 120:

Description of the Existing Environ

- Page 121 and 122:

Description of the Existing Environ

- Page 123 and 124:

Description of the Existing Environ

- Page 125 and 126:

Description of the Existing Environ

- Page 127 and 128:

gis no. 833-6-25b Job No. 833-6 Oct

- Page 129 and 130:

Description of the Existing Environ

- Page 131 and 132:

Description of the Existing Environ

- Page 133 and 134:

Description of the Existing Environ

- Page 135 and 136:

Description of the Existing Environ

- Page 137 and 138:

Description of the Existing Environ

- Page 139 and 140:

Description of the Existing Environ

- Page 141 and 142:

Description of the Existing Environ

- Page 143 and 144:

Description of the Existing Environ

- Page 145 and 146:

Description of the Existing Environ

- Page 147 and 148:

Description of the Existing Environ

- Page 149 and 150:

Description of the Existing Environ

- Page 151 and 152:

Description of the Existing Environ

- Page 153 and 154:

Description of the Existing Environ

- Page 155 and 156:

Description of the Existing Environ

- Page 157 and 158:

Description of the Existing Environ

- Page 159 and 160:

Description of the Existing Environ

- Page 161 and 162:

Description of the Existing Environ

- Page 163 and 164:

Description of the Existing Environ

- Page 165 and 166:

Description of the Existing Environ

- Page 167 and 168:

Description of the Existing Environ

- Page 169 and 170:

Description of the Existing Environ

- Page 171 and 172:

7. IDENTIFICATION OF POTENTIAL ENVI

- Page 173 and 174:

Identification of Potential Environ

- Page 175 and 176:

Identification of Potential Environ

- Page 177 and 178:

Identification of Potential Environ

- Page 179 and 180:

Identification of Potential Environ

- Page 181 and 182:

Identification of Potential Environ

- Page 183 and 184:

Identification of Potential Environ

- Page 185 and 186:

Identification of Potential Environ

- Page 187 and 188:

Identification of Potential Environ

- Page 189 and 190:

Identification of Potential Environ

- Page 191 and 192:

Identification of Potential Environ

- Page 193 and 194:

Identification of Potential Environ

- Page 195 and 196:

Identification of Potential Environ

- Page 197 and 198:

Identification of Potential Environ

- Page 199 and 200:

Identification of Potential Environ

- Page 201 and 202:

Identification of Potential Environ

- Page 203 and 204:

Identification of Potential Environ

- Page 205 and 206:

Identification of Potential Environ

- Page 207 and 208:

Identification of Potential Environ

- Page 209 and 210:

Identification of Potential Environ

- Page 211 and 212:

8. IDENTIFICATION OF POTENTIALCUMUL

- Page 213 and 214:

Identification of Potential Cumulat

- Page 215 and 216:

Identification of Potential Cumulat

- Page 217 and 218:

9. ENVIRONMENTAL PLANSTM

- Page 219 and 220:

Environmental Plans• Occupational

- Page 221 and 222:

Environmental Plans• to restore l

- Page 223 and 224:

Environmental Plansbenefits of root

- Page 225 and 226:

ReferencesAdrian D’Hont, GNWT ENR

- Page 227 and 228:

ReferencesFriesen, B.F. 1975. Poten

- Page 229 and 230:

ReferencesMartens, H. E. 2007. Ekat

- Page 231 and 232:

ReferencesRescan Environmental Serv

- Page 233 and 234:

ReferencesWalton, L. R., H. D. Cluf

- Page 235:

A1 - PART 1 FORM (ENGLISH)TM

- Page 257:

A3 - PART 1 FORM (INUINNAQTUN)TM

- Page 269 and 270:

Non-Technical Project Proposal Desc

- Page 271 and 272:

ᐱᓕᕆᐊᒃᓴᒧᑦ (ᐅᔭᕋ

- Page 273 and 274:

A6 - NON-TECHNICAL DESCRIPTION (INU

- Page 275 and 276:

A7 - PART 2 FORM: PROJECT SPECIFICI

- Page 277 and 278:

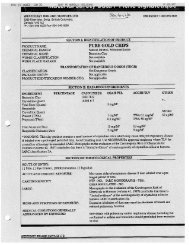

Project Specific Information Requir

- Page 279 and 280:

Project Specific Information Requir

- Page 281 and 282:

Project Specific InformationThe fol

- Page 283 and 284:

Project Specific Information Requir

- Page 285 and 286:

Project Specific Information Requir

- Page 287 and 288:

Project Specific Information Requir

- Page 289 and 290:

Project Specific Information Requir

- Page 291 and 292:

Project Specific Information Requir

- Page 293 and 294:

Project Specific Information Requir

- Page 295 and 296:

Description of the Existing Environ

- Page 297 and 298:

APPENDIX BSITE PHOTOSTM

- Page 299 and 300:

Braided outflow of Cleaver Basin du

- Page 301 and 302:

Near shore habitat of Anne Lake. Th

- Page 303 and 304:

P.O. BOX 119GJOA HAVEN, NU X0B 1J0T

- Page 305 and 306:

Licence Number: 2BE-HAK0709LICENCE

- Page 307 and 308:

Licence Number: 2BE-HAK0709PART A:S

- Page 309 and 310:

Licence Number: 2BE-HAK0709hold all

- Page 311 and 312:

Licence Number: 2BE-HAK0709and plan

- Page 313 and 314:

Licence Number: 2BE-HAK07092. All a

- Page 315 and 316:

Licence Number: 2BE-HAK0709only in

- Page 317 and 318:

Licence Number: 2BE-HAK0709iii.the

- Page 319 and 320:

Effective June 16, 2006Map 1 - West

- Page 321 and 322:

Effective June 16, 2006Easternmost

- Page 323 and 324:

Effective June 16, 2006The planned

- Page 325 and 326:

Effective June 16, 2006Camp Inciner

- Page 327 and 328:

Effective June 16, 2006on the prope

- Page 329 and 330:

NIRB Screening Yes No If no, date

- Page 331 and 332:

Effective June 16, 2006Name (Print)

- Page 337 and 338:

go towww.raymac.com>call1-866-753-6