6 - Vicat

6 - Vicat

6 - Vicat

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

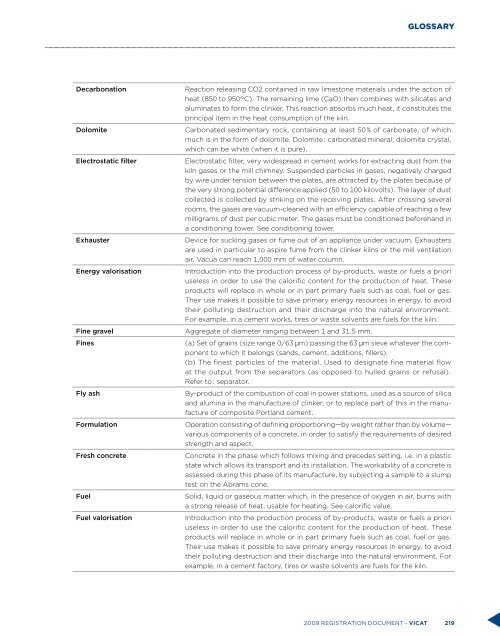

GLOSSARYDecarbonationDolomiteElectrostatic filterExhausterEnergy valorisationFine gravelFinesFly ashFormulationFresh concreteFuelFuel valorisationReaction releasing CO2 contained in raw limestone materials under the action ofheat (850 to 950°C). The remaining lime (CaO) then combines with silicates andaluminates to form the clinker. This reaction absorbs much heat, it constitutes theprincipal item in the heat consumption of the kiln.Carbonated sedimentary rock, containing at least 50 % of carbonate, of whichmuch is in the form of dolomite. Dolomite : carbonated mineral, dolomite crystal,which can be white (when it is pure).Electrostatic filter, very widespread in cement works for extracting dust from thekiln gases or the mill chimney. Suspended particles in gases, negatively chargedby wire under tension between the plates, are attracted by the plates because ofthe very strong potential difference applied (50 to 100 kilovolts). The layer of dustcollected is collected by striking on the receiving plates. After crossing severalrooms, the gases are vacuum-cleaned with an efficiency capable of reaching a fewmilligrams of dust per cubic meter. The gases must be conditioned beforehand ina conditioning tower. See conditioning tower.Device for sucking gases or fume out of an appliance under vacuum. Exhaustersare used in particular to aspire fume from the clinker kilns or the mill ventilationair. Vacua can reach 1,000 mm of water column.Introduction into the production process of by-products, waste or fuels a prioriuseless in order to use the calorific content for the production of heat. Theseproducts will replace in whole or in part primary fuels such as coal, fuel or gas.Their use makes it possible to save primary energy resources in energy, to avoidtheir polluting destruction and their discharge into the natural environment.For example, in a cement works, tires or waste solvents are fuels for the kiln.Aggregate of diameter ranging between 1 and 31.5 mm.(a) Set of grains (size range 0/63 µm) passing the 63 µm sieve whatever the componentto which it belongs (sands, cement, additions, fillers).(b) The finest particles of the material. Used to designate fine material flowat the output from the separators (as opposed to hulled grains or refusal).Refer to : separator.By-product of the combustion of coal in power stations, used as a source of silicaand alumina in the manufacture of clinker, or to replace part of this in the manufactureof composite Portland cement.Operation consisting of defining proportioning—by weight rather than by volume—various components of a concrete, in order to satisfy the requirements of desiredstrength and aspect.Concrete in the phase which follows mixing and precedes setting, i.e. in a plasticstate which allows its transport and its installation. The workability of a concrete isassessed during this phase of its manufacture, by subjecting a sample to a slumptest on the Abrams cone.Solid, liquid or gaseous matter which, in the presence of oxygen in air, burns witha strong release of heat, usable for heating. See calorific value.Introduction into the production process of by-products, waste or fuels a prioriuseless in order to use the calorific content for the production of heat. Theseproducts will replace in whole or in part primary fuels such as coal, fuel or gas.Their use makes it possible to save primary energy resources in energy, to avoidtheir polluting destruction and their discharge into the natural environment. Forexample, in a cement factory, tires or waste solvents are fuels for the kiln.2009 registration document - VICAT 219