6 - Vicat

6 - Vicat

6 - Vicat

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

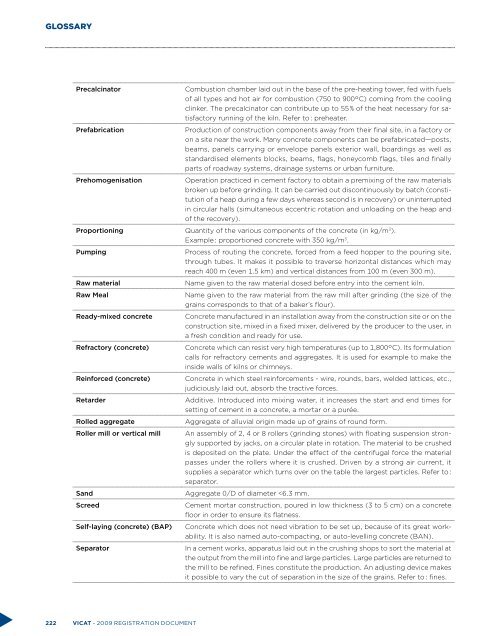

GLOSSARYPrecalcinatorCombustion chamber laid out in the base of the pre-heating tower, fed with fuelsof all types and hot air for combustion (750 to 900°C) coming from the coolingclinker. The precalcinator can contribute up to 55 % of the heat necessary for satisfactoryrunning of the kiln. Refer to : preheater.PrefabricationProduction of construction components away from their final site, in a factory oron a site near the work. Many concrete components can be prefabricated—posts,beams, panels carrying or envelope panels exterior wall, boardings as well asstandardised elements blocks, beams, flags, honeycomb flags, tiles and finallyparts of roadway systems, drainage systems or urban furniture.PrehomogenisationOperation practiced in cement factory to obtain a premixing of the raw materialsbroken up before grinding. It can be carried out discontinuously by batch (constitutionof a heap during a few days whereas second is in recovery) or uninterruptedin circular halls (simultaneous eccentric rotation and unloading on the heap andof the recovery).Proportioning Quantity of the various components of the concrete (in kg/m 3 ).Example : proportioned concrete with 350 kg/m 3 .PumpingProcess of routing the concrete, forced from a feed hopper to the pouring site,through tubes. It makes it possible to traverse horizontal distances which mayreach 400 m (even 1.5 km) and vertical distances from 100 m (even 300 m).Raw materialName given to the raw material dosed before entry into the cement kiln.Raw MealName given to the raw material from the raw mill after grinding (the size of thegrains corresponds to that of a baker’s flour).Ready-mixed concrete Concrete manufactured in an installation away from the construction site or on theconstruction site, mixed in a fixed mixer, delivered by the producer to the user, ina fresh condition and ready for use.Refractory (concrete)Concrete which can resist very high temperatures (up to 1,800°C). Its formulationcalls for refractory cements and aggregates. It is used for example to make theinside walls of kilns or chimneys.Reinforced (concrete)Concrete in which steel reinforcements - wire, rounds, bars, welded lattices, etc.,judiciously laid out, absorb the tractive forces.RetarderAdditive. Introduced into mixing water, it increases the start and end times forsetting of cement in a concrete, a mortar or a purée.Rolled aggregateAggregate of alluvial origin made up of grains of round form.Roller mill or vertical mill An assembly of 2, 4 or 8 rollers (grinding stones) with floating suspension stronglysupported by jacks, on a circular plate in rotation. The material to be crushedis deposited on the plate. Under the effect of the centrifugal force the materialpasses under the rollers where it is crushed. Driven by a strong air current, itsupplies a separator which turns over on the table the largest particles. Refer to :separator.SandAggregate 0/D of diameter