6 - Vicat

6 - Vicat

6 - Vicat

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

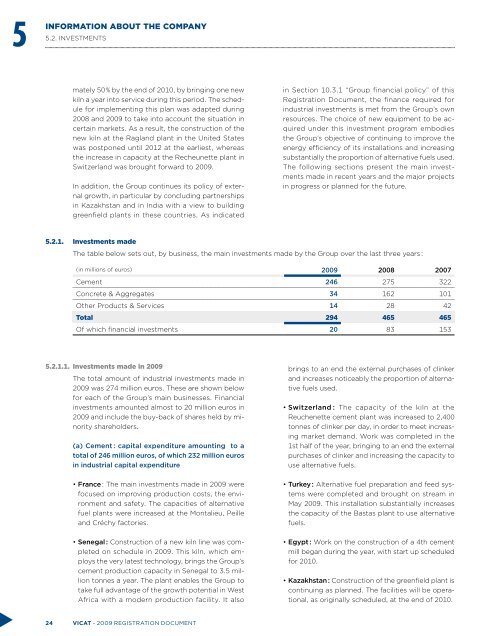

5INFORMATION ABOUT THE COMPANY5.2. INVESTMENTSmately 50 % by the end of 2010, by bringing one newkiln a year into service during this period. The schedulefor implementing this plan was adapted during2008 and 2009 to take into account the situation incertain markets. As a result, the construction of thenew kiln at the Ragland plant in the United Stateswas postponed until 2012 at the earliest, whereasthe increase in capacity at the Recheunette plant inSwitzerland was brought forward to 2009.In addition, the Group continues its policy of externalgrowth, in particular by concluding partnershipsin Kazakhstan and in India with a view to buildinggreenfield plants in these countries. As indicatedin Section 10.3.1 “Group financial policy” of thisRegistration Document, the finance required forindustrial investments is met from the Group’s ownresources. The choice of new equipment to be acquiredunder this investment program embodiesthe Group’s objective of continuing to improve theenergy efficiency of its installations and increasingsubstantially the proportion of alternative fuels used.The following sections present the main investmentsmade in recent years and the major projectsin progress or planned for the future.5.2.1. Investments madeThe table below sets out, by business, the main investments made by the Group over the last three years :(in millions of euros) 2009 2008 2007Cement 246 275 322Concrete & Aggregates 34 162 101Other Products & Services 14 28 42Total 294 465 465Of which financial investments 20 83 1535.2.1.1. Investments made in 2009The total amount of industrial investments made in2009 was 274 million euros. These are shown belowfor each of the Group’s main businesses. Financialinvestments amounted almost to 20 million euros in2009 and include the buy-back of shares held by minorityshareholders.(a) Cement : capital expenditure amounting to atotal of 246 million euros, of which 232 million eurosin industrial capital expenditure• France : The main investments made in 2009 werefocused on improving production costs, the environmentand safety. The capacities of alternativefuel plants were increased at the Montalieu, Peilleand Créchy factories.• Senegal : Construction of a new kiln line was completedon schedule in 2009. This kiln, which employsthe very latest technology, brings the Group’scement production capacity in Senegal to 3.5 milliontonnes a year. The plant enables the Group totake full advantage of the growth potential in WestAfrica with a modern production facility. It alsobrings to an end the external purchases of clinkerand increases noticeably the proportion of alternativefuels used.• Switzerland : The capacity of the kiln at theReuchenette cement plant was increased to 2,400tonnes of clinker per day, in order to meet increasingmarket demand. Work was completed in the1st half of the year, bringing to an end the externalpurchases of clinker and increasing the capacity touse alternative fuels.• Turkey : Alternative fuel preparation and feed systemswere completed and brought on stream inMay 2009. This installation substantially increasesthe capacity of the Bastas plant to use alternativefuels.• Egypt : Work on the construction of a 4th cementmill began during the year, with start up scheduledfor 2010.• Kazakhstan : Construction of the greenfield plant iscontinuing as planned. The facilities will be operational,as originally scheduled, at the end of 2010.24 VICAT - 2009 registration document