Untitled - MetosExpo - Free

Untitled - MetosExpo - Free

Untitled - MetosExpo - Free

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

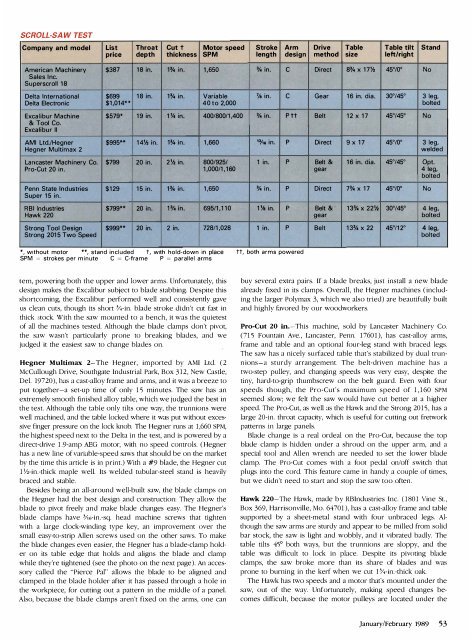

SCROLL-SA W TESTCompany and model List Throat Cut t Motor speed Stroke Arm Drive Table Table tilt Standleft/rightprice depth thickness SPM length design method sizeAmerican MachinerySales Inc.Superscroll 18$38718 in. 1% in. 1,650 3/4 in. C Direct 8% x 17 45°/0° NoDelta International $699 18 in. 1% in. Variable % in. C Gear 16 in. dia. 30°/45° 3 leg,Delta Electronic $1,014** 40 to 2,000 boltedExcalibur Machine $579* 19 in. 1% in. 4001800/1 ,400 3,4 in. Ptt Belt 12 x 17 45°/45° No& Tool Co.Excalibur IIAMI Ltd.lHegner $995** 14 in. 1% in. 1,660Hegner Multimax 2Lancaster Machinery Co. $799 20 in. 2 in. 80019251Pro-Cut 20 in. 1,000/1 ,160Penn State Industries $129 15 in. 1% in. 1,650Super 15 in.13118 in. P Di rect 9 x 17 45°/0° 3 leg,welded1 in. P Belt & 16 in. dia. 45°/45° Opt.gear4 leg,3,4 in. boltedP Direct 7% x 17 45°/0° NoRBI Industries $799** 20 in. 13/4 in. 69511 ,1 10Hawk 220= = =Strong Tool Design $999** 20 in. 2 in. 72811 ,028Strong 201 5 Two Speed*. Without motor **. stand included t, With hold-down In placeSPM strokes per minute C C-frame P parallel armstem, powering both the upper and lower arms. Unfortunately, thisdesign makes the Excalibur subject to blade stabbing. Despite thisshortcoming, the Excalibur performed well and consistently gaveus clean cuts, though its short %-in. blade stroke didn't cut fast inthick tock. With the saw mounted to a bench, it was the quietestof all the machines tested. Although the blade clamps don't pivot,the saw wasn't particularly prone to breaking blades, and wejudged it the easiest saw to change blades on.Hegner Multimax 2-The Hegner, imported by AMI Ltd. (2McCullough Drive, Southgate Industrial Park, Box 312, New Castle,Del. 19720), has a cast-alloy frame and arms, and it was a breeze toput together-a set-up time of only 15 minutes. The saw has anextremely smooth fi nished alloy table, which we judged the best inthe test. Although the table only tilts one way, the trunnions werewell machined, and the table locked where it was put without excessivefinger pressure on dle lock knob. TIle Hegner runs at 1,660 SPM,the highest speed next to the Delta in the test, and is powered by adirect-drive 1.9-amp AEG motor, with no speed controls. (Hegnerhas a new line of variable-speed saws dlat should be on the marketby the time this article is in print.) With a #9 blade, the Hegner cut1 Y2-in.-thick maple well. Its welded tubular-steel stand is heavilybraced and stable.Besides being an all-around well-built saw, the blade clamps onthe Hegner had the best design and construction: They allow theblade to pivot freely and make blade changes easy. The Hegner'sblade clamps have 3/t6-in.-sq. head machine screws that tightenwith a large clock-winding type key, an improvement over thesmall easy-to-strip Allen screws used on the other saws. To makethe blade changes even easier, the Hegner has a blade-clamp holderon its table edge that holds and aligns the blade and clampwhile they're tightened (see the photo on the next page). An accessorycalled the "Pierce Pal" allows the blade to be aligned andclamped in the blade holder after it has passed through a hole inthe workpiece, for cutting out a pattern in the middle of a panel.Also, because the blade clamps aren't fixed on the arms, one can11A1 in. P Belt & 13% x 22 30°/45° 4 leg,gearbolted1 in. P Belt 130/4 x 22 45°112° 4 leg,boltedtt. both arms poweredbuy several extra pairs. If a blade breaks, just install a new bladealready fixed in its clamps. Overall, the Hegner machines (includingthe larger Polymax 3, which we also tried) are beautifully builtand highly favored by our woodworkers.Pro-Cut 20 in.-This machine, sold by Lancaster Machinery Co.(715 Fountain Ave., Lancaster, Penn. 17601), has cast-alloy arms,frame and table and an optional four-leg stand with braced legs.The saw has a nicely surfaced table that's stabilized by dual trunnions-asturdy arrangement. The belt-driven machine has atwo-step pulley, and changing speeds was very easy, despite thetiny, hard-to-grip thumbscrew on the belt guard. Even with fourspeeds though, the Pro-Cut's maximum speed of 1,160 SPMseemed slow; we felt the saw would have cut better at a higherspeed. The Pro-Cut, as well as the Hawk and the Strong 2015, has alarge 20-in. throat capaCity, which is useful for cutting out fretworkpatterns in large panels.Blade change is a real ordeal on the Pro-Cut, because the topblade clamp is hidden under a shroud on dle upper arm, and aspecial tool and Allen wrench are needed to set the lower bladeclamp. The Pro-Cut comes with a foot pedal on/off switch thatplugs into the cord. This feature came in handy a couple of times,but we didn't need to start and stop dle saw too often.Hawk 220-The Hawk, made by RBIndustries Inc. (1801 Vine St.,Box 369, Harrisonville, Mo. 64701), has a cast-alloy frame and tablesupported by a sheet-metal stand with four unbraced legs. Aldl0Ughdle saw arms are sturdy and appear to be milled from solidbar stock, the saw is light and wobbly, and it vibrated badly. Thetable tilts 45° both ways, but the trunnions are sloppy, and thetable was difficult to lock in place. Despite its pivoting bladeclamps, the saw broke more than its share of blades and wasprone to burning in dle kerf when we cut l%-in.-thick oak.The Hawk has two speeds and a motor that's mounted under thesaw, out of dle way. Unfortunately, making speed changes becomesdifficult, because the motor pulleys are located under theJanuary/February 1989 53