Besides providing a pivoting blade clamp that prevents blade breakage by allowing a blade to flex during cutting, the Hegner has a built-inholder that supports and aligns a blade in the clamp while it's tightened in place.saw. Two different length V-belts are required, one for each sawspeed pulley. Blade change requires a special rod and an Allenwrench to secure the pivoting top blade clamp. The blade tensioning/releaseadjustment features a convenient cam lock that takesonly a flick to engage or loosen for blade changes.Strong 2015 Two Speed-This saw, made by Strong Tool Design(20425 Benrice, Livonia, Mich. 48152), has a cast-alloy frame, an1)sand large 13%-in. by 22-in. table. The stand has four legs that aresplayed in lieu of bracing to give the saw stability, but we foundthe legs to be always in the way. The table surface was adequatelysmooth, but the single trunnion didn't lock well enough to keepthe table steady when cutting heavy work. The hold-down can bebolted on either side of the frame, making it easier for left-handers.Cuts with the 2015 were generally smootil, but the light saw vibratedconSiderably. A few times after tightening the blade-tensioningadjustment, the pivot on the end of tile bolt didn't engage correctlyand tension would suddenly release in tlle middle of the cut. Theblade clamps are designed to pivot with the blade, but unfortunately,arm design makes the blade move back on the downstroke.Blade changes were relatively easy with the provided Allen wrench.One problem, however, is that tlle lower blade clamp barely fitstilrough tlle table, so the blade needs to be bent and workedthrough the opening. Since our test, the 2015 has been supercededby a new model, the Strong Prospector, also witll a 20-in. throat.Super 15 in.-This saw is the least-expensive saw in the sample: afraction of the price of the $1,014 Delta, the most expensive sawwe tested. Manufactured in Taiwan and imported by Penn State Industries(2850 Comly Road, Philadelphia, Penn. 19154), the Super 15looks like the Hegner and is remarkably similar to Taiwanese sawssold by Grizzly and Delta. Altllough Penn State's ads claim the sawhas professional quality and precision, it simply doesn't. The overallquality of the castings and the saw's fit and finish is poor. Forinstance, the Super 15 has a dleap plastic hold-down and minisculepump bellows that are absolutely useless. Also, the blade clampsare badly machined and don't grip the blade well.Like the Pro-Cut 20 in., the Super 15 features a covered top armfor safety. But on the unit we received for testing, tlle cover hadbeen bent, and the arm hit it on every stroke, making a terriblesound until we bent it back to shape. On the positive side, the sawcan cut clean l y enough (albeit with a lot of vibration), no doubtthanks to its high 1,650 SPM. Also, the Super 15, like the Superscroll18, has a power-switch lock so it can be child-proofed.Superscroll l8-Imported by American Machinery Sales Inc. (Box5285, Marshallton, Del. 19809), this Taiwan-made saw is heftilybuilt and doesn't offer many frills. Although the table surfacingand machining are still pretty rough, this saw is a step up fromtlle Super 15, both in capaCity and performance. The Superscroll's18-in.-deep throat is enough for fairly large work, and with itshold-down in place, the saw has the same depth-cutting capaCity ofmost other, more expensive scroll saws. The saw is a hybrid design:It features direct drive, like many parallel-arm saws, but is aC-frame saw, like the Delta.The Superscroll 18 has pivoting blade clamps that allow for afair amount of blade flex. Plastic hinged covers fl ip over the bladeclamps (I can't see why), and a removable table insert makes accessingtlle lower arm for blade changes easier. The Superscroll 18produced a moderate amount of vibration during cutting, whichdecreased when we bolted tlle saw to a heavy workbench. Cuttingaction was solid and yielded smooth cuts in all but thick hardwoods.Overall, the Superscroll 18 is a lot of saw for the money.Other models-As interest in scroll saws grows, manufacturerscontinue to offer additional models, which we were unable to includein this test. Companies offering other scroll saws includeAMT, Grizzly, Sunhill, Sakura U.S.A. and Transpower. DGreg Bover is the woodshop foreman of CB. Fisk lnc., pipe-organmakers in Gloucester, Mass. Sbop members Rob Hazard and JohnSchreiner helped with the testing for this article.54 Fine Woodworking

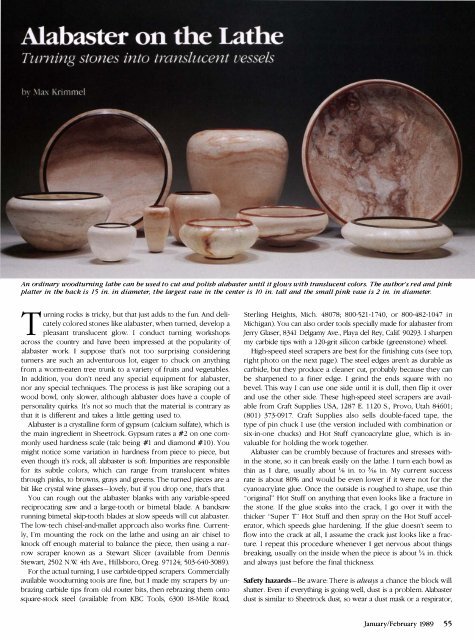

An ordinary woodturning lathe can be used to cut and polish alabaster until it glows with translucent colors. The author's red and pinkplatter in the back is 15 in. in diameter, the largest vase in the center is 10 in. tall and the small pink vase is 2 in. in diameter.Turning rocks is tricky, but that just adds to the fun. And delicatelycolored stones like alabaster, when turned, develop apleasant translucent glow. I conduct turning workshopsacross the country and have been impressed at the popularity oalabaster work. I suppose that's not too surprising consideringturners are such an adventurous lot, eager to chuck on anythingfrom a worm-eaten tree trunk to a variety of fruits and vegetables.In addition, you don't need any special equipment for alabaster,nor any special techniques. The process is just like scraping out awood bowl, only slower, although alabaster does have a couple ofpersonality quirks. It's not so much that the material is contrary asthat it is different and takes a little getting used to.Alabaster is a crystalline form of gypsum (calcium sulfate), which isthe main ingredient in Sheetrock. Gypsum rates a #2 on one commonlyused hardness scale (talc being #1 and diamond #10). Youmight notice some variation in hardness from piece to piece, buteven though it's rock, all alabaster is soft. Impurities are responsiblefor its subtle colors, which can range from translucent whitesthrough pinks, to browns, grays and greens. The turned pieces are abit like crystal wine glasses-lovely, but if you drop one, that's that.You can rough out the alabaster blanks with any variable-speedreCiprocating saw and a large-tootl1 or bimetal blade. A bandsawrunning bimetal skip-tooth blades at slow speeds will cut alabaster.The low-tech chisel-and-mallet approach also works fine. Currently,I'm mounting the rock on the lathe and using an air chisel toknock off enough material to balance the piece, then using a narrowscraper known as a Stewart Slicer (available from DennisStewart, 2502 N.W 4th Ave., Hillsboro, Oreg. 97124; 503-640-3089).For the actual turning, I use carbide-tipped scrapers. Commerciallyavailable woodturning tools are fine, but I made my scrapers by unbraZingcarbide tips from old router bits, then rebrazing them ontosquare-stock steel (available from KBC Tools, 6300 18-Mile Road,Sterling Heights, Mich. 48078; 800-521-1740, or 800-482-1047 inMichigan). You can also order tools specially made for alabaster fromJerry Glaser, 8341 Delgamy Ave., Playa del Rey, Calif. 90293. I sharpenmy carbide tips with a 120-grit silicon carbide (greenstone) wheel.High-speed steel scrapers are best for the finishing cuts (see top,right photo on the next page). The steel edges aren't as durable ascarbide, but they produce a cleaner cut, probably because tl1ey canbe sharpened to a finer edge. I grind tl1e ends square with nobevel. This way I can use one side until it is dull, then flip it overand use the other side. These high-speed steel scrapers are availablefrom Craft Supplies USA, 1287 E. 1120 S., Provo, Utah 84601;(801) 373-0917. Craft Supplies also sells double-faced tape, thetype of pin chuck I use (the version included with combination orsix-in-one chucks) and Hot Stuff cyanoacrylate glue, which is invaluablefor holding the work together.Alabaster can be crumbly because of fractures and stresses withinthe stone, so it can break easily on the lathe. I turn each bowl asthin as I dare, usually about Vs in. to 0/16 in. My current successrate is about 80% and would be even lower if it were not for thecyanoacrylate glue. Once the outside is roughed to shape, use thin"original" Hot Stuff on anything that even looks like a fracture inthe stone. If the glue soaks into the crack, I go over it with thethicker "Super T" Hot Stuff and then spray on the Hot Stuff accelerator,which speeds glue hardening. If the glue doesn't seem toflow into the crack at all, I assume the crack just looks like a fracture.I repeat this procedure whenever I get nervous about tl1ingsbreaking, usually on the inside when the piece is about 1/4 in. thickand always just before the final thickness.Safety hazards-Be aware: There is always a chance the block willshatter. Even if everything is going well, dust is a problem. Alabasterdust is similar to Sheetrock dust, so wear a dust mask or a respirator,January/February 1989 55

- Page 3 and 4: FineW> rktng'_' ______ ___ January/

- Page 6 and 7: Letters (contillued)never hurt hims

- Page 8 and 9: MetiJods of Wo rkedited and drawn b

- Page 10 and 11: Methods of Wo rk (contillued)exampl

- Page 12 and 13: Making a door sandwichI intend to m

- Page 14 and 15: Q & A (colltillued)of a bad situati

- Page 16 and 17: Pollou'-upby Dick BurrowsMore on to

- Page 18 and 19: Easy toStep by Step DrawingsBuildOn

- Page 20 and 21: (25 years)P-SOO20" PlANERSEATTLE:1

- Page 22 and 23: There areover 4,000money-savingreas

- Page 24 and 25: READY TO ASSEMBLE-SOLID-CHERRYWALNU

- Page 26 and 27: THE BARTLEYBUNDLES!AlJ.500 ·24"Ban

- Page 28 and 29: A GREAT DEA.L IMORE (f)5 HP, 3 Ph3

- Page 30 and 31: --ANTIQUE & USED TOOLSQuality, olde

- Page 32 and 33: PhoneStater--- - -[][]Ur:iTheWoodwo

- Page 34 and 35: """""',' Universal Precision Measu

- Page 36 and 37: FineWorking January/February 1989M

- Page 38 and 39: Once the backrest plaques are joine

- Page 41 and 42: Fig. 4:.1:iim.lf1lmllli.iiiiie?tII

- Page 43 and 44: Secret compartments were so common

- Page 45 and 46: -----.JFig. 4: Hanging tray below t

- Page 47 and 48: Tbree examples of the author's slid

- Page 49 and 50: worked but will maintain a crisp, s

- Page 53: SCROLL-SA W TESTCompany and model L

- Page 57 and 58: use a dust collector, and if possib

- Page 59 and 60: I've never been especially fond of

- Page 61 and 62: and it shields your fingers from ex

- Page 63 and 64: The cabinet scraper used by the aut

- Page 65 and 66: Fig. 2: Post:Modern Table Top, 52 i

- Page 67 and 68: Fig. 3: LFI TableNut is fastened to

- Page 69 and 70: Fig. 3: Curved miterPattern doesn't

- Page 71 and 72: Selections from the author's sketch

- Page 73 and 74: thor anticipate problems and make f

- Page 75 and 76: Fig. 2: Air flowMoist air exits thr

- Page 77 and 78: lating fan. The idea here is to ins

- Page 79 and 80: Long prized by woodworkers for its

- Page 81 and 82: A Chinese woodworker assembles an e

- Page 83 and 84: Chinese shaping toolsThroughout Chi

- Page 85 and 86: Using a Holtzapffel ornamental lath

- Page 87 and 88: NOW! BUY BRIDGEWOOD IN CANADA . ..

- Page 89: QiUl j!! IIIc:Ul.=:c ...!!

- Page 92 and 93: 111,"11SIOPm'EI.I,lu it ....IS •

- Page 94 and 95: CARBIDE TIPPED ROUTER BITSPRCAL PRO

- Page 96: FS Tool CorporationP.o. Box 510, 21

- Page 99 and 100: ... !Ij*;::""' eMore NTS 14-5614" H

- Page 101 and 102: FI:\ISHI:\G SLPPLIESIf you have bee

- Page 103 and 104: T\UNTONPUBliCATIONS... by fellow en

- Page 105 and 106:

PmeWqqQWorkingIndex to issues 66 th

- Page 107 and 108:

FowlerFowler, Brian, chair by, 67,1

- Page 109 and 110:

ScrewsZimmerScrews:brace driving of

- Page 111 and 112:

34-76 1 10' Uni s-l-l/2 hp ........

- Page 113 and 114:

MOISTURE METERFAMOUS "MINI-LiGNO"MA

- Page 115 and 116:

Dependable extra hands for all type

- Page 117 and 118:

MIRRORA· THE HAND MIRRORCOMPLEMENT

- Page 119 and 120:

£'Delrl.lnc'e To Manufacture Quali