Untitled - MetosExpo - Free

Untitled - MetosExpo - Free

Untitled - MetosExpo - Free

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

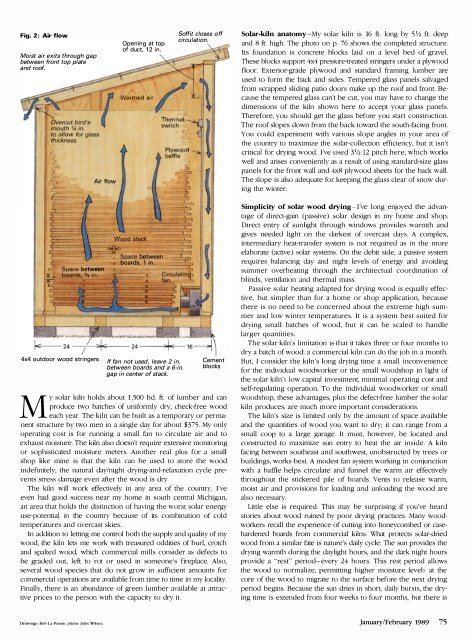

Fig. 2: Air flowMoist air exits through gapbetween front top plateand roof.Air flowOpening at topof duct, 12 in.Soffit closes offcirculation., ..."..-:::=.-:I?-=_..J "I___....._=-;3_.-J.-,.r --c::'__ 1'--.= d.:----L...,:=!:----: .::-=----·8-Space between." boards, 1 in.-I-between- ... \1....___ II. -- . ICirculatin---- 24 -------24 ----4x4 outdoor wood stringersIf fa n not used, leave 2 in.between boards and a 6-in.gap in center of stack.CementblocksMy solar kiln holds about 1,500 bd. ft. of lumber and canproduce twO batches of uniformly dry, check-free woodeach year. The kiln can be built as a temporary or pennanentstructure by two men in a single day for about $375. My onlyoperating cost is for running a small fan to circulate air and toexhaust moisture. The kiln also doesn't require extensive monitoringor sophisticated moisture meters. Another real plus for a smallshop like mine is that the kiln can be used to store the woodindefinitely; the natural day/night drying-and-relaxation cycle preventsstress damage even after the wood is dry.The kiln will work effectively in any area of the country. I'veeven had good success near my home in south central Michigan,an area that holds the distinction of having the worst solar energyuse-potential in the country because of its combination of coldtemperatures and overcast skies.In addition to letting me conu'ol both the supply and quality of mywood, the kiln lets me work with treasured oddities of burl, crotchand spalted wood, which commercial mills consider as defects tobe graded out, left to rot or used in someone's fireplace. Also,several wood species that do not grow in sufficient amounts forconunercial operations are available from time to time in my locality.Finally, there is an abundance of green lumber available at attractiveprices to the person with the capacity to dry it.Solar-kiln anatomy-My solar kiln is 16 ft. long by 5Yz ft. deepand 8 ft. high. The photo on p. 76 shows the completed structure.Its foundation is concrete blocks laid on a level bed of gravel.These blocks support 4x4 pressure-treated stringers under a plywoodfloor. Exterior-grade plywood and standard framing lumber areused to form the back and sides. Tempered glass panels salvagedfrom scrapped sliding patio doors make up the roof and front. Becausethe tempered glass can't be cut, you may have to change thedimensions of the kiln shown here to accept your glass panels.Therefore, you should get the glass before you start construction.The roof slopes down from the back toward the south-facing front.You could experiment with various slope angles in your area ofthe country to maximize the solar-collection efficiency, but it isn'tcritical for drying wood. I've used 3Yz:12 pitch here, which workswell and arises conveniently as a result of using standard·size glasspanels for the front wall and 4x8 plywood sheets for the back wall.The slope is also adequate for keeping the glass clear of snow duringthe winter.Simplicity of solar wood drying- I've long enjoyed the advantageof direct-gain (passive) solar design in my home and shop.Direct entry of sunlight through windows provides warmth andgives needed light on the darkest of overcast days. A complex,intermediary heat-transfer system is not required as in the moreelaborate (active) solar systems. On the debit side, a passive systemrequires balancing day and night levels of energy and avoidingsummer overheating through the architectual coordination ofblinds, ventilation and thermal mass.Passive solar heating adapted for drying wood is equally effective,but simpler than for a home or shop application, becausethere is no need to be concerned about the extreme high summerand low winter temperatures. It is a system best suited fordrying small batches of wood, but it can be scaled to handlelarger quantities.The solar kiln's limitation is that it takes three or four months todry a batch of wood; a commercial kiln can do the job in a month.But, I consider the kiln's long drying time a small inconveniencefor the individual woodworker or the small woods hop in light ofthe solar kiln' low capital investment, minimal operating cost andself-regulating operation. To the individual woodworker or smallwoodshop, these advantages, plus the defect-free lumber the solarkiln produces, are much more important considerations.The kiln's size is limited only by the amount of space availableand the quantities of wood you want to dry; it can range from asmall coop to a large garage. It must, however, be located andconstructed to maximize sun entry to heat the air inside. A kilnfacing between southeast and southwest, unobstructed by trees orbuildings, works best. A modest fan system working in conjunctionwith a baffle helps circulate and funnel the warm air effectivelythroughout the stickered pile of boards. Vents to release warm,moist air and provisions for loading and unloading the wood arealso necessary.Little else is required. This may be surprising if you've heardstories about wood ruined by poor drying practices. Many woodworkersrecall the experience of cutting into honeycombed or casehardenedboards from commercial kilns. What protects solar-driedwood from a similar fate is nature's daily cycle: The sun provides thedrying warmth during the daylight hours, and the dark night hoursprovide a "rest" period-every 24 hours. This rest period allowsthe wood to normalize, permitting higher moisture level at thecore of the wood to migrate to the surface before the next dryingperiod begins. Because the sun dries in short, daily bursts, the dryingtime is extended from four weeks to four months, but there isL..'l Drawings: Bob Pointe; photo: John WilsonJanuary/February 1989 75