WINTER 2016

Distributor's Link Magazine Winter Issue 2016 / Vol 39 No1

Distributor's Link Magazine Winter Issue 2016 / Vol 39 No1

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

166 THE DISTRIBUTOR’S LINK<br />

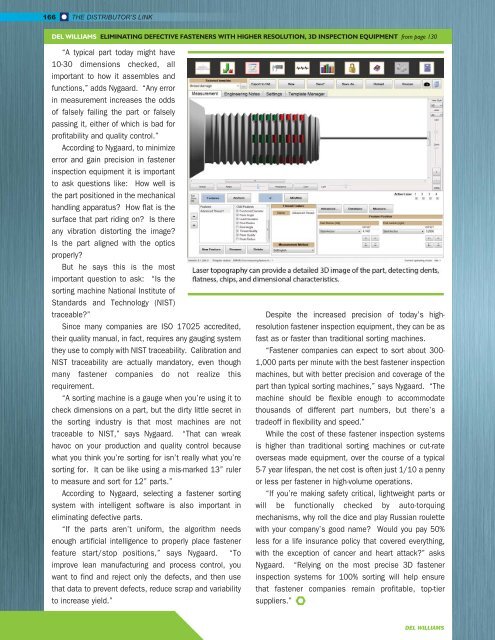

DEL WILLIAMS ELIMINATING DEFECTIVE FASTENERS WITH HIGHER RESOLUTION, 3D INSPECTION EQUIPMENT from page 130<br />

“A typical part today might have<br />

10-30 dimensions checked, all<br />

important to how it assembles and<br />

functions,” adds Nygaard. “Any error<br />

in measurement increases the odds<br />

of falsely failing the part or falsely<br />

passing it, either of which is bad for<br />

profitability and quality control.”<br />

According to Nygaard, to minimize<br />

error and gain precision in fastener<br />

inspection equipment it is important<br />

to ask questions like: How well is<br />

the part positioned in the mechanical<br />

handling apparatus? How flat is the<br />

surface that part riding on? Is there<br />

any vibration distorting the image?<br />

Is the part aligned with the optics<br />

properly?<br />

But he says this is the most<br />

important question to ask: “Is the<br />

sorting machine National Institute of<br />

Standards and Technology (NIST)<br />

traceable?”<br />

Since many companies are ISO 17025 accredited,<br />

their quality manual, in fact, requires any gauging system<br />

they use to comply with NIST traceability. Calibration and<br />

NIST traceability are actually mandatory, even though<br />

many fastener companies do not realize this<br />

requirement.<br />

“A sorting machine is a gauge when you’re using it to<br />

check dimensions on a part, but the dirty little secret in<br />

the sorting industry is that most machines are not<br />

traceable to NIST,” says Nygaard. “That can wreak<br />

havoc on your production and quality control because<br />

what you think you’re sorting for isn’t really what you’re<br />

sorting for. It can be like using a mis-marked 13” ruler<br />

to measure and sort for 12” parts.”<br />

According to Nygaard, selecting a fastener sorting<br />

system with intelligent software is also important in<br />

eliminating defective parts.<br />

“If the parts aren’t uniform, the algorithm needs<br />

enough artificial intelligence to properly place fastener<br />

feature start/stop positions,” says Nygaard. “To<br />

improve lean manufacturing and process control, you<br />

want to find and reject only the defects, and then use<br />

that data to prevent defects, reduce scrap and variability<br />

to increase yield.”<br />

Despite the increased precision of today’s highresolution<br />

fastener inspection equipment, they can be as<br />

fast as or faster than traditional sorting machines.<br />

“Fastener companies can expect to sort about 300-<br />

1,000 parts per minute with the best fastener inspection<br />

machines, but with better precision and coverage of the<br />

part than typical sorting machines,” says Nygaard. “The<br />

machine should be flexible enough to accommodate<br />

thousands of different part numbers, but there’s a<br />

tradeoff in flexibility and speed.”<br />

While the cost of these fastener inspection systems<br />

is higher than traditional sorting machines or cut-rate<br />

overseas made equipment, over the course of a typical<br />

5-7 year lifespan, the net cost is often just 1/10 a penny<br />

or less per fastener in high-volume operations.<br />

“If you’re making safety critical, lightweight parts or<br />

will be functionally checked by auto-torquing<br />

mechanisms, why roll the dice and play Russian roulette<br />

with your company’s good name? Would you pay 50%<br />

less for a life insurance policy that covered everything,<br />

with the exception of cancer and heart attack?” asks<br />

Nygaard. “Relying on the most precise 3D fastener<br />

inspection systems for 100% sorting will help ensure<br />

that fastener companies remain profitable, top-tier<br />

suppliers.”<br />

DEL WILLIAMS