2007_6_Nr6_EEMJ

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Lazar et al. /Environmental Engineering and Management Journal 6 (<strong>2007</strong>), 6, 529-535<br />

Treatment methods are grouped in two<br />

categories: non-destructive (condensation, adsorption,<br />

membrane separation) or destructive (thermal<br />

incinerators, catalytic incinerators, catalytic photodegradation,<br />

and bio-degradation. The nondestructive<br />

techniques allow the recovery of the<br />

solvents for their use as raw material, while the<br />

destructive techniques are utilized for oxidative<br />

treatment of VOC emissions, with recovery of the<br />

heat resulted in the process (EPA, 1995; Dumitriu and<br />

Hulea, 1999). Selection of a certain treatment method<br />

is done considering: the process that generates<br />

pollutant emissions with VOC, the nature and flow of<br />

the emission, the minimum, average and maximum<br />

concentrations of VOC, the costs etc. These criteria<br />

involve a good management of the solvents within the<br />

technological phases of the activities that lead to<br />

VOC emissions (EPA, 1995; Lazaroiu, 2000).<br />

4. The mass balance of the solvents in a plant for<br />

surfaces degreasing<br />

4.1. Solvents management<br />

Within a technological process for surface<br />

covering with decorative-protective purposes, a stage<br />

for chemical degreasing in organic solvents is<br />

foreseen aiming at partially removal of the animal and<br />

soluble vegetal fats. Usually, degreasing occurs in a<br />

cave with a parallelepiped shape, containing a<br />

covering device and manufactured by materials<br />

resistant to the action of the solvents.<br />

Due to degreasing of the metallic surfaces in<br />

organic solvents, result VOC emissions that should be<br />

controlled such as the emission limit value,<br />

concordant to the solvent consumption threshold, not<br />

to be exceeded. The control of these emissions<br />

involves a good management of the solvents,<br />

consisting in establishment of the mass balance for<br />

the degreasing industrial activity. The solvent<br />

consumption for a range of 12 months is determined<br />

through the mass balance, and the proof of fulfilling<br />

certain requirements regarding the limit value of<br />

fugitive and total emissions, respective, in accordance<br />

to the regulation is achieved (Table 1).<br />

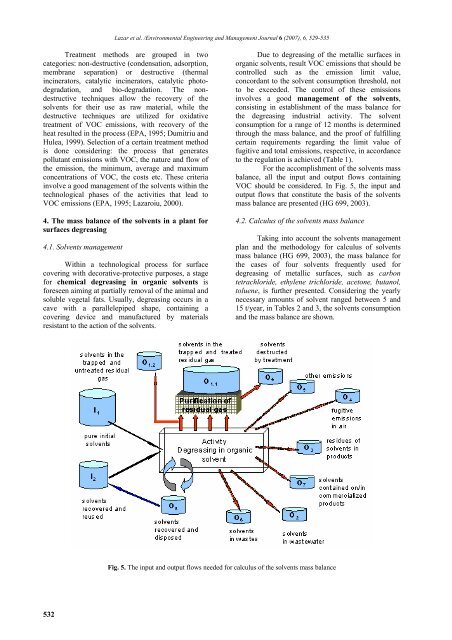

For the accomplishment of the solvents mass<br />

balance, all the input and output flows containing<br />

VOC should be considered. In Fig. 5, the input and<br />

output flows that constitute the basis of the solvents<br />

mass balance are presented (HG 699, 2003).<br />

4.2. Calculus of the solvents mass balance<br />

Taking into account the solvents management<br />

plan and the methodology for calculus of solvents<br />

mass balance (HG 699, 2003), the mass balance for<br />

the cases of four solvents frequently used for<br />

degreasing of metallic surfaces, such as carbon<br />

tetrachloride, ethylene trichloride, acetone, butanol,<br />

toluene, is further presented. Considering the yearly<br />

necessary amounts of solvent ranged between 5 and<br />

15 t/year, in Tables 2 and 3, the solvents consumption<br />

and the mass balance are shown.<br />

Fig. 5. The input and output flows needed for calculus of the solvents mass balance<br />

532