2007_6_Nr6_EEMJ

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Sustainable irrigation based on intelligent optimization of nutrients applications<br />

The irrigation module is set up at the level of<br />

the mobile arms of the automatic irrigation system<br />

and it is made up of the communication interface<br />

IPCL, the microchip control device µP, the radio<br />

receiver RR and the electro valve EV. On the MI<br />

module movement, the identification of the<br />

membership to a characterization cell is performed on<br />

the grounds of the entering its range of action. The<br />

emission power of the sensors modules MS is limited<br />

within the cell and towards its detection there<br />

interferes the criterion of the emission maximum.<br />

Following the communication settlement<br />

between the sensors module transmitter and the<br />

irrigation module receiver, the data are transmitted by<br />

the command device µP to the PLC interface, joined<br />

with the supply circuit of the operative electrical<br />

engine (Sohag et al., 2005). By the PLC transmission<br />

the useful information is received by the control<br />

centre CC, on a computer server. As a consequence of<br />

the interpretation of the response type data provided<br />

by the characterization cells sensors are taken the<br />

control decisions of reaching the limits of the<br />

nutrients concentrations and relative humidity<br />

imposed by the data basis. The quality and quantity<br />

commands are transmitted by the PLC system to the<br />

nutrients injection batteries, providing the combine<br />

irrigation agent to the pulverization nozzles, to the<br />

volume controlling electro valves belonging to the<br />

irrigation module.<br />

By the communication system PLC useful data<br />

are delivered as modulated signal. The signal is of the<br />

broadband type and the physical environment enables<br />

multiple operations roll on the same existent<br />

infrastructure.<br />

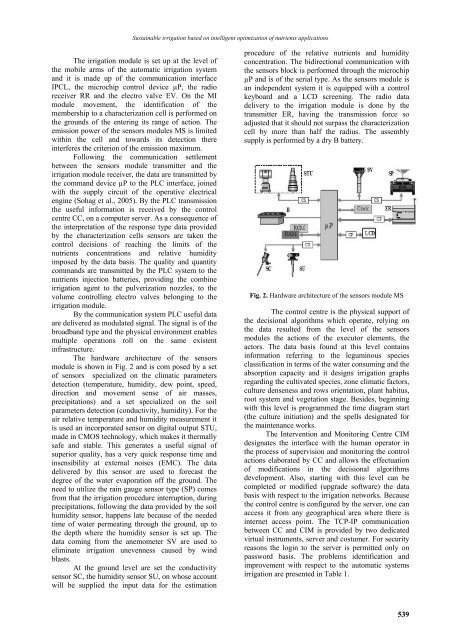

The hardware architecture of the sensors<br />

module is shown in Fig. 2 and is com posed by a set<br />

of sensors specialized on the climatic parameters<br />

detection (temperature, humidity, dew point, speed,<br />

direction and movement sense of air masses,<br />

precipitations) and a set specialized on the soil<br />

parameters detection (conductivity, humidity). For the<br />

air relative temperature and humidity measurement it<br />

is used an incorporated sensor on digital output STU,<br />

made in CMOS technology, which makes it thermally<br />

safe and stable. This generates a useful signal of<br />

superior quality, has a very quick response time and<br />

insensibility at external noises (EMC). The data<br />

delivered by this sensor are used to forecast the<br />

degree of the water evaporation off the ground. The<br />

need to utilize the rain gauge sensor type (SP) comes<br />

from that the irrigation procedure interruption, during<br />

precipitations, following the data provided by the soil<br />

humidity sensor, happens late because of the needed<br />

time of water permeating through the ground, up to<br />

the depth where the humidity sensor is set up. The<br />

data coming from the anemometer SV are used to<br />

eliminate irrigation unevenness caused by wind<br />

blasts.<br />

At the ground level are set the conductivity<br />

sensor SC, the humidity sensor SU, on whose account<br />

will be supplied the input data for the estimation<br />

procedure of the relative nutrients and humidity<br />

concentration. The bidirectional communication with<br />

the sensors block is performed through the microchip<br />

µP and is of the serial type. As the sensors module is<br />

an independent system it is equipped with a control<br />

keyboard and a LCD screening. The radio data<br />

delivery to the irrigation module is done by the<br />

transmitter ER, having the transmission force so<br />

adjusted that it should not surpass the characterization<br />

cell by more than half the radius. The assembly<br />

supply is performed by a dry B battery.<br />

Fig. 2. Hardware architecture of the sensors module MS<br />

The control centre is the physical support of<br />

the decisional algorithms which operate, relying on<br />

the data resulted from the level of the sensors<br />

modules the actions of the executor elements, the<br />

actors. The data basis found at this level contains<br />

information referring to the leguminous species<br />

classification in terms of the water consuming and the<br />

absorption capacity and it designs irrigation graphs<br />

regarding the cultivated species, zone climatic factors,<br />

culture denseness and rows orientation, plant habitus,<br />

root system and vegetation stage. Besides, beginning<br />

with this level is programmed the time diagram start<br />

(the culture initiation) and the spells designated for<br />

the maintenance works.<br />

The Intervention and Monitoring Centre CIM<br />

designates the interface with the human operator in<br />

the process of supervision and monitoring the control<br />

actions elaborated by CC and allows the effectuation<br />

of modifications in the decisional algorithms<br />

development. Also, starting with this level can be<br />

completed or modified (upgrade software) the data<br />

basis with respect to the irrigation networks. Because<br />

the control centre is configured by the server, one can<br />

access it from any geographical area where there is<br />

internet access point. The TCP-IP communication<br />

between CC and CIM is provided by two dedicated<br />

virtual instruments, server and costumer. For security<br />

reasons the login to the server is permitted only on<br />

password basis. The problems identification and<br />

improvement with respect to the automatic systems<br />

irrigation are presented in Table 1.<br />

539