HMI software for CNC controls

HMI software for CNC controls

HMI software for CNC controls

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

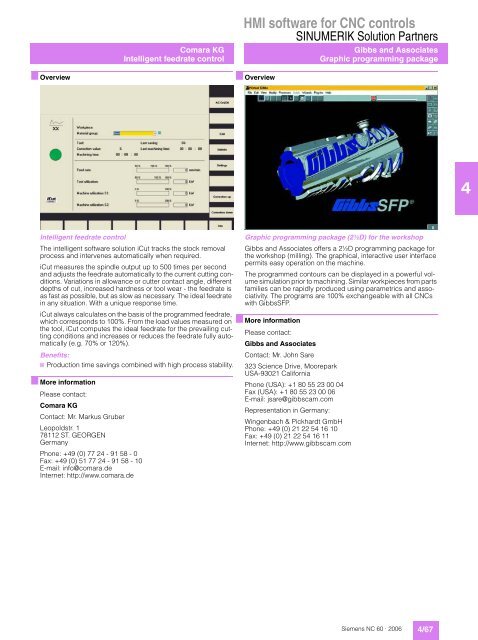

■ Overview<br />

Comara KG<br />

Intelligent feedrate control<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

SINUMERIK Solution Partners<br />

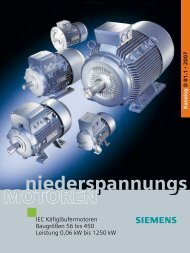

Gibbs and Associates<br />

Graphic programming package<br />

■ Overview<br />

Intelligent feedrate control<br />

Graphic programming package (2½D) <strong>for</strong> the workshop<br />

The intelligent <strong>software</strong> solution iCut tracks the stock removal Gibbs and Associates offers a 2½D programming package <strong>for</strong><br />

process and intervenes automatically when required.<br />

the workshop (milling). The graphical, interactive user interface<br />

iCut measures the spindle output up to 500 times per second<br />

permits easy operation on the machine.<br />

and adjusts the feedrate automatically to the current cutting con- The programmed contours can be displayed in a powerful volditions.<br />

Variations in allowance or cutter contact angle, different ume simulation prior to machining. Similar workpieces from parts<br />

depths of cut, increased hardness or tool wear - the feedrate is families can be rapidly produced using parametrics and asso-<br />

as fast as possible, but as slow as necessary. The ideal feedrate ciativity. The programs are 100% exchangeable with all <strong>CNC</strong>s<br />

in any situation. With a unique response time.<br />

with GibbsSFP.<br />

iCut always calculates on the basis of the programmed feedrate,<br />

which corresponds to 100%. From the load values measured on ■ More in<strong>for</strong>mation<br />

the tool, iCut computes the ideal feedrate <strong>for</strong> the prevailing cutting<br />

conditions and increases or reduces the feedrate fully auto-<br />

Please contact:<br />

matically (e.g. 70% or 120%).<br />

Gibbs and Associates<br />

Benefits:<br />

Contact: Mr. John Sare<br />

7 Production time savings combined with high process stability. 323 Science Drive, Moorepark<br />

■ More in<strong>for</strong>mation<br />

USA-93021 Cali<strong>for</strong>nia<br />

Phone (USA): +1 80 55 23 00 04<br />

Please contact:<br />

Comara KG<br />

Contact: Mr. Markus Gruber<br />

Leopoldstr. 1<br />

78112 ST. GEORGEN<br />

Germany<br />

Phone: +49 (0) 77 24 - 91 58 - 0<br />

Fax: +49 (0) 51 77 24 - 91 58 - 10<br />

E-mail: info@comara.de<br />

Internet: http://www.comara.de<br />

Fax (USA): +1 80 55 23 00 06<br />

E-mail: jsare@gibbscam.com<br />

Representation in Germany:<br />

Wingenbach & Pickhardt GmbH<br />

Phone: +49 (0) 21 22 54 16 10<br />

Fax: +49 (0) 21 22 54 16 11<br />

Internet: http://www.gibbscam.com<br />

Siemens NC 60 · 2006<br />

4/67<br />

4