HMI software for CNC controls

HMI software for CNC controls

HMI software for CNC controls

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

SINUMERIK Solution Partners<br />

Klaus Müller VIDEO VISION GmbH<br />

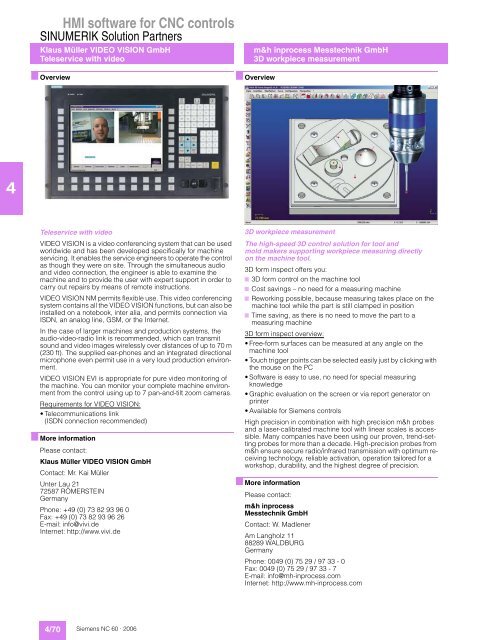

Teleservice with video<br />

■ Overview<br />

Teleservice with video<br />

VIDEO VISION is a video conferencing system that can be used<br />

worldwide and has been developed specifically <strong>for</strong> machine<br />

servicing. It enables the service engineers to operate the control<br />

as though they were on site. Through the simultaneous audio<br />

and video connection, the engineer is able to examine the<br />

machine and to provide the user with expert support in order to<br />

carry out repairs by means of remote instructions.<br />

VIDEO VISION NM permits flexible use. This video conferencing<br />

system contains all the VIDEO VISION functions, but can also be<br />

installed on a notebook, inter alia, and permits connection via<br />

ISDN, an analog line, GSM, or the Internet.<br />

In the case of larger machines and production systems, the<br />

audio-video-radio link is recommended, which can transmit<br />

sound and video images wirelessly over distances of up to 70 m<br />

(230 ft). The supplied ear-phones and an integrated directional<br />

microphone even permit use in a very loud production environment.<br />

VIDEO VISION EVI is appropriate <strong>for</strong> pure video monitoring of<br />

the machine. You can monitor your complete machine environment<br />

from the control using up to 7 pan-and-tilt zoom cameras.<br />

Requirements <strong>for</strong> VIDEO VISION:<br />

• Telecommunications link<br />

(ISDN connection recommended)<br />

■ More in<strong>for</strong>mation<br />

Please contact:<br />

Klaus Müller VIDEO VISION GmbH<br />

Contact: Mr. Kai Müller<br />

Unter Lau 21<br />

72587 RÖMERSTEIN<br />

Germany<br />

Phone: +49 (0) 73 82 93 96 0<br />

Fax: +49 (0) 73 82 93 96 26<br />

E-mail: info@vivi.de<br />

Internet: http://www.vivi.de<br />

4/70<br />

Siemens NC 60 · 2006<br />

m&h inprocess Messtechnik GmbH<br />

3D workpiece measurement<br />

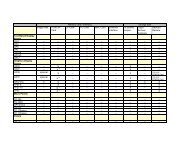

■ Overview<br />

3D workpiece measurement<br />

The high-speed 3D control solution <strong>for</strong> tool and<br />

mold makers supporting workpiece measuring directly<br />

on the machine tool.<br />

3D <strong>for</strong>m inspect offers you:<br />

7 3D <strong>for</strong>m control on the machine tool<br />

7 Cost savings – no need <strong>for</strong> a measuring machine<br />

7 Reworking possible, because measuring takes place on the<br />

machine tool while the part is still clamped in position<br />

7 Time saving, as there is no need to move the part to a<br />

measuring machine<br />

3D <strong>for</strong>m inspect overview:<br />

• Free-<strong>for</strong>m surfaces can be measured at any angle on the<br />

machine tool<br />

• Touch trigger points can be selected easily just by clicking with<br />

the mouse on the PC<br />

• Software is easy to use, no need <strong>for</strong> special measuring<br />

knowledge<br />

• Graphic evaluation on the screen or via report generator on<br />

printer<br />

• Available <strong>for</strong> Siemens <strong>controls</strong><br />

High precision in combination with high precision m&h probes<br />

and a laser-calibrated machine tool with linear scales is accessible.<br />

Many companies have been using our proven, trend-setting<br />

probes <strong>for</strong> more than a decade. High-precision probes from<br />

m&h ensure secure radio/infrared transmission with optimum receiving<br />

technology, reliable activation, operation tailored <strong>for</strong> a<br />

workshop, durability, and the highest degree of precision.<br />

■ More in<strong>for</strong>mation<br />

Please contact:<br />

m&h inprocess<br />

Messtechnik GmbH<br />

Contact: W. Madlener<br />

Am Langholz 11<br />

88289 WALDBURG<br />

Germany<br />

Phone: 0049 (0) 75 29 / 97 33 - 0<br />

Fax: 0049 (0) 75 29 / 97 33 - 7<br />

E-mail: info@mh-inprocess.com<br />

Internet: http://www.mh-inprocess.com