Abstract Download (8.38MB)

Abstract Download (8.38MB)

Abstract Download (8.38MB)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Name (Title):<br />

Kohsaku Kawakami (MANA Researcher, Senior Researcher)<br />

Affiliation:<br />

International Center for Materials Nanoarchitectonics<br />

(MANA) and Biomaterials Center, NIMS<br />

Address:<br />

1-1 Namiki, Tsukuba. Ibaraki 305-0044, Japan<br />

Email: KAWAKAMI.Kohsaku@nims.go.jp<br />

Home Page: http://www.nims.go.jp/bmc/group/ndg/kawakami/<br />

Presentation Title:<br />

Electrospray Deposition as a New Method for Preparing Fine Drug Particles<br />

Poster Session PB-3<br />

<strong>Abstract</strong>:<br />

Although there has been much discussion on favorable physicochemical properties for drug<br />

candidates over the last decade, formulators must still deal with many challenging compounds<br />

including poorly soluble drugs. A novel formulation technology, electrospray deposition method,<br />

is introduced in this presentation. This method enabled amorphization and micronization of the<br />

formulation, both of which contribute to improvement of the solubility, in one-step preparation<br />

procedure.<br />

Electrospray Deposition (called as “Electrospinning” in polymer science field) has been<br />

regarded as a promising method to prepare various fibrous materials such as filters, sensors, and<br />

many types of biomedical materials. Various poorly soluble drugs including predonisolone<br />

(PDN), phenylbutazone, phenytoin and carbamazepine were dissolved with polymeric carriers<br />

including polyvinylpyrroridone (PVP), Eudragid E-100, and polyethylene glycol either in ethanol<br />

or in its aqueous solution. The solutions were introduced to 8-pin manifold using a syringe pump,<br />

followed by application of high voltage, typically in the range of 10-25 kV, to produce<br />

electrospray to a stainless steel target. The setup was enclosed in an air- tight box to control<br />

humidity of the environment. The dried particles were collected from the target surface.<br />

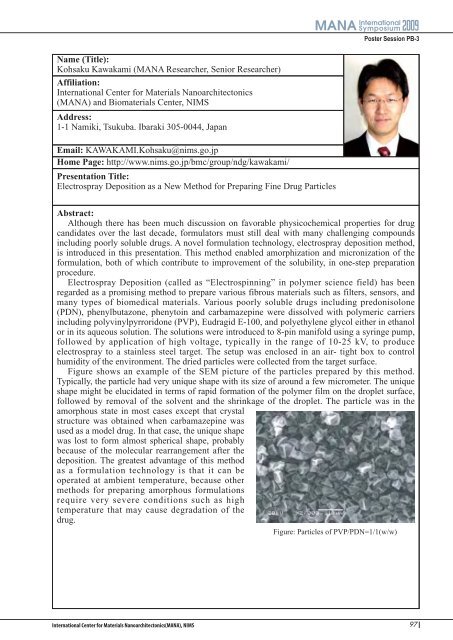

Figure shows an example of the SEM picture of the particles prepared by this method.<br />

Typically, the particle had very unique shape with its size of around a few micrometer. The unique<br />

shape might be elucidated in terms of rapid formation of the polymer film on the droplet surface,<br />

followed by removal of the solvent and the shrinkage of the droplet. The particle was in the<br />

amorphous state in most cases except that crystal<br />

structure was obtained when carbamazepine was<br />

used as a model drug. In that case, the unique shape<br />

was lost to form almost spherical shape, probably<br />

because of the molecular rearrangement after the<br />

deposition. The greatest advantage of this method<br />

as a formulation technology is that it can be<br />

operated at ambient temperature, because other<br />

methods for preparing amorphous formulations<br />

require very severe conditions such as high<br />

temperature that may cause degradation of the<br />

drug.<br />

Figure: Particles of PVP/PDN=1/1(w/w)<br />

97