click here to download - UniKL MIMET Official Website

click here to download - UniKL MIMET Official Website

click here to download - UniKL MIMET Official Website

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Diffusion bonding is a joining process between<br />

materials w<strong>here</strong>in the principal mechanism for<br />

joint formation is solid state diffusion. Coales‐<br />

cence of the faying surface is accomplished<br />

through the application of pressure at evevated<br />

temperature. No melting and only limited macro‐<br />

scopic deformation or relative motion of the parts<br />

occurs during bonding. Microscopic deformation<br />

followed by recrystallization occurs. Near the<br />

bond zone, self diffusion in the same materials<br />

and inter diffusion between the materials takes<br />

place simultaneously. New crystalline forms of the<br />

original elements and inter‐metallic compounds<br />

may grow during the process (Paulonis, “Diffusion<br />

Welding and Brazing”).<br />

Other terms which are sometimes used synony‐<br />

mously with diffusion bonding include diffusion<br />

welding, solid state bonding, pressure bonding,<br />

isostatic bonding , and hot press bonding.<br />

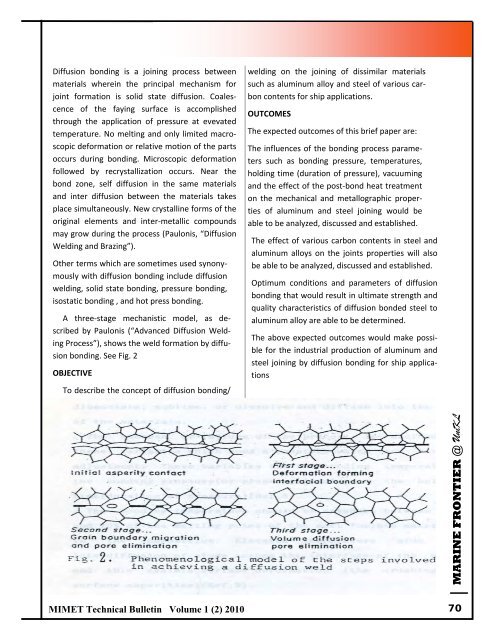

A three‐stage mechanistic model, as de‐<br />

scribed by Paulonis (“Advanced Diffusion Weld‐<br />

ing Process”), shows the weld formation by diffu‐<br />

sion bonding. See Fig. 2<br />

OBJECTIVE<br />

To describe the concept of diffusion bonding/<br />

<strong>MIMET</strong> Technical Bulletin Volume 1 (2) 2010<br />

welding on the joining of dissimilar materials<br />

such as aluminum alloy and steel of various car‐<br />

bon contents for ship applications.<br />

OUTCOMES<br />

The expected outcomes of this brief paper are:<br />

The influences of the bonding process parame‐<br />

ters such as bonding pressure, temperatures,<br />

holding time (duration of pressure), vacuuming<br />

and the effect of the post‐bond heat treatment<br />

on the mechanical and metallographic proper‐<br />

ties of aluminum and steel joining would be<br />

able <strong>to</strong> be analyzed, discussed and established.<br />

The effect of various carbon contents in steel and<br />

aluminum alloys on the joints properties will also<br />

be able <strong>to</strong> be analyzed, discussed and established.<br />

Optimum conditions and parameters of diffusion<br />

bonding that would result in ultimate strength and<br />

quality characteristics of diffusion bonded steel <strong>to</strong><br />

aluminum alloy are able <strong>to</strong> be determined.<br />

The above expected outcomes would make possi‐<br />

ble for the industrial production of aluminum and<br />

steel joining by diffusion bonding for ship applica‐<br />

tions<br />

| MARINE FRONTIER @ <strong>UniKL</strong><br />

70