- Page 1 and 2:

Proceedings e report 67

- Page 3 and 4:

Wood science for conservation of cu

- Page 5 and 6:

SUMMARY Introduction ..............

- Page 7 and 8:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 9 and 10:

INTRODUCTION These proceedings of a

- Page 11 and 12:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 13:

(A) MATERIAL PROPERTIES

- Page 16 and 17:

SORPTION OF MOISTURE AND DIMENSIONA

- Page 18 and 19:

SORPTION OF MOISTURE AND DIMENSIONA

- Page 20 and 21:

SORPTION OF MOISTURE AND DIMENSIONA

- Page 22 and 23:

VIBRATIONAL PROPERTIES OF TROPICAL

- Page 24 and 25:

VIBRATIONAL PROPERTIES OF TROPICAL

- Page 26 and 27:

VIBRATIONAL PROPERTIES OF TROPICAL

- Page 28 and 29:

CREEP PROPERTIES OF HEAT TREATED WO

- Page 30 and 31:

CREEP PROPERTIES OF HEAT TREATED WO

- Page 32 and 33:

CREEP PROPERTIES OF HEAT TREATED WO

- Page 34 and 35:

MEASUREMENT OF THE ELASTIC PROPERTI

- Page 36 and 37:

ELASTIC PROPERTIES OF MINUTE SAMPLE

- Page 38 and 39:

4. Results Young's modulus (10^4 Mp

- Page 40 and 41:

PREDICTION OF LINEAR DIMENSIONAL CH

- Page 42 and 43:

DIMENSIONAL CHANGE OF UNRESTRICTED

- Page 44 and 45:

DIMENSIONAL CHANGE OF UNRESTRICTED

- Page 46 and 47:

AGEING OF WOOD - DESCRIBED BY THE A

- Page 48 and 49:

AGEING OF WOOD - DESCRIBED BY THE A

- Page 50 and 51:

AGEING OF WOOD - DESCRIBED BY THE A

- Page 52 and 53:

90 30 0 3,0E-03 - 2,0E 2,0E-03 - 1,

- Page 54 and 55:

4. Application HYGRO-LOCK INTEGRATI

- Page 56 and 57:

RESEARCH ON THE AGING OF WOOD IN RI

- Page 58 and 59:

RESEARCH ON THE AGING OF WOOD IN RI

- Page 60 and 61:

Xylarium Database RESEARCH ON THE A

- Page 62 and 63:

AGING WOOD FROM CULTURAL PROPERTIES

- Page 64 and 65:

AGING WOOD FROM CULTURAL PROPERTIES

- Page 66 and 67:

STRENGTH AND MOE OF POPLAR WOOD (PO

- Page 68 and 69:

STRENGTH AND MOE OF POPLAR WOOD ACR

- Page 70 and 71:

STRENGTH AND MOE OF POPLAR WOOD ACR

- Page 72 and 73:

PHOTODEGRADATION AND THERMAL DEGRAD

- Page 74 and 75:

PHOTODEGRADATION AND THERMAL DEGRAD

- Page 76 and 77:

PHOTODEGRADATION AND THERMAL DEGRAD

- Page 79 and 80:

ROMANIAN WOODEN CHURCHES WALL PAINT

- Page 81 and 82:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 83 and 84:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 85 and 86:

DISINFECTION AND CONSOLIDATION BY I

- Page 87 and 88:

3. Results and discussion WOOD SCIE

- Page 89 and 90:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 91 and 92:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 93 and 94:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 95 and 96:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 97 and 98:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 99 and 100:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 101 and 102:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 103 and 104:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 105 and 106:

FUNGAL DECONTAMINATION BY COLD PLAS

- Page 107 and 108:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 109 and 110:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 111 and 112:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 113 and 114:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 115 and 116:

STUDIES ON INSECT DAMAGES OF WOODEN

- Page 117 and 118:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 119 and 120:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 121 and 122:

TERMITE INFESTATION RISK IN PORTUGU

- Page 123 and 124: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 125 and 126: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 127 and 128: BIODETERIORATION OF CULTURAL HERITA

- Page 129 and 130: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 131 and 132: 4. Causes of biodeterioration WOOD

- Page 133 and 134: DEGRADATION OF MELANIN AND BIOCIDES

- Page 135 and 136: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 137 and 138: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 139 and 140: MOULD ON ORGANS AND CULTURAL HERITA

- Page 141 and 142: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 143 and 144: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 145 and 146: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 147 and 148: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 149 and 150: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 151 and 152: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 153 and 154: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 155 and 156: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 157 and 158: RESEARCH STUDY ON THE EFFECTS OF TH

- Page 159 and 160: 4. Methodology WOOD SCIENCE FOR CON

- Page 161: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 165 and 166: NON DESTRUCTIVE IMAGING FOR WOOD ID

- Page 167 and 168: METHODS OF NON-DESTRUCTIVE WOOD TES

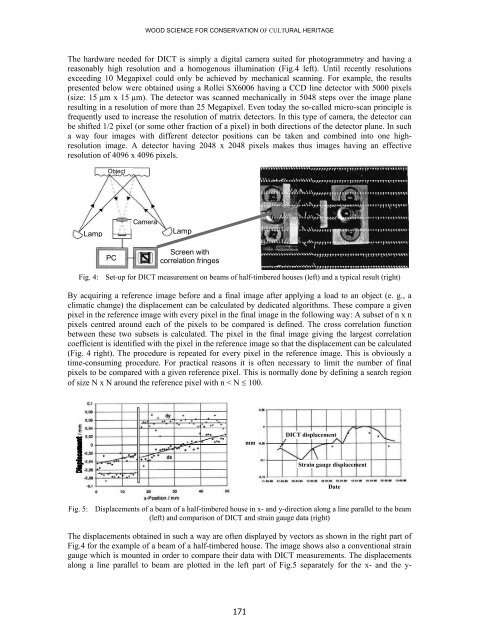

- Page 169 and 170: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 171 and 172: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 173: MEASUREMENT AND SIMULATION OF DIMEN

- Page 177 and 178: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 179 and 180: IN THE HEART OF THE LIMBA TREE (TER

- Page 181 and 182: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 183 and 184: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 185 and 186: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 187 and 188: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 189 and 190: 3. Conclusions WOOD SCIENCE FOR CON

- Page 191 and 192: 2. Materials and methods WOOD SCIEN

- Page 193 and 194: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 195 and 196: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 197 and 198: 3. Chemometrics WOOD SCIENCE FOR CO

- Page 199 and 200: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 201 and 202: 3. Results and discussion WOOD SCIE

- Page 203 and 204: NIR SPECTROSCOPIC MONITORING OF WAT

- Page 205 and 206: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 207 and 208: NUMERICAL SIMULATION OF THE STRENGT

- Page 209 and 210: 3. Methods and models WOOD SCIENCE

- Page 211 and 212: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 213 and 214: SIMPLE ELECTRONIC SPECKLE PATTERN I

- Page 215 and 216: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 217 and 218: 5. Conclusions WOOD SCIENCE FOR CON

- Page 219 and 220: WOOD SCIENCE FOR CONSERVATION OF CU

- Page 221 and 222: Average r adiated presure field (dB

- Page 223 and 224: EXPERIMENTAL AND NUMERICAL MECHANIC

- Page 225 and 226:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 227 and 228:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 229 and 230:

EFFECT OF THERMAL TREATMENT ON STRU

- Page 231 and 232:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 233 and 234:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 235 and 236:

The aims of this work are to: WOOD

- Page 237 and 238:

ultramarine [bad] titanium white [m

- Page 239 and 240:

4. Conclusions chrome yellow WOOD S

- Page 241 and 242:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 243 and 244:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 245 and 246:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 247 and 248:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 249 and 250:

Fig. 7 - A soaked lamella clamped i

- Page 251 and 252:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 253:

(D) CONSERVATION

- Page 256 and 257:

EUROPEAN TECHNICAL COMMITTEE 346 -

- Page 258 and 259:

EUROPEAN TECHNICAL COMMITTEE 346 -

- Page 260 and 261:

EUROPEAN TECHNICAL COMMITTEE 346 -

- Page 262 and 263:

EUROPEAN TECHNICAL COMMITTEE 346 -

- Page 264 and 265:

THE WRECK OF VROUW MARIA - CURRENT

- Page 266 and 267:

THE WRECK OF VROUW MARIA - CURRENT

- Page 268 and 269:

THE WRECK OF VROUW MARIA - CURRENT

- Page 270 and 271:

ROMANIAN ARCHITECTURAL WOODEN CULTU

- Page 272 and 273:

ROMANIAN ARCHITECTURAL WOODEN CULTU

- Page 274 and 275:

ROMANIAN ARCHITECTURAL WOODEN CULTU

- Page 276 and 277:

RESSURREIÇÃO DE CRISTO - PANEL FR

- Page 278 and 279:

ON 18 TH- AND 19 TH- CENTURY SACRIS

- Page 280 and 281:

ON 18TH- AND 19TH- CENTURY SACRISTY

- Page 282 and 283:

ON 18TH- AND 19TH- CENTURY SACRISTY

- Page 284 and 285:

ON 18TH- AND 19TH- CENTURY SACRISTY

- Page 286 and 287:

DEFIBRING OF HISTORICAL ROOF BEAM C

- Page 288 and 289:

DEFIBRING OF HISTORICAL ROOF BEAM C

- Page 290 and 291:

DEFIBRING OF HISTORICAL ROOF BEAM C

- Page 292 and 293:

EXAMINATION AND CONSERVATION OF TWO

- Page 294 and 295:

EXAMINATION AND CONSERVATION OF TWO

- Page 296 and 297:

THE CONSEQUENCES OF WOODEN STRUCTUR

- Page 298 and 299:

CONSEQUENCES OF WOODEN STRUCTURES C

- Page 301 and 302:

WHAT ONE NEEDS TO KNOW FOR THE ASSE

- Page 303 and 304:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 305 and 306:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 307 and 308:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 309 and 310:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 311 and 312:

load (KN) Samples 6 5 4 3 2 1 WOOD

- Page 313 and 314:

STRUCTURAL BEHAVIOUR OF TRADITIONAL

- Page 315 and 316:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 317 and 318:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 319 and 320:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 321 and 322:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 323 and 324:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 325:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 329 and 330:

INVESTIGATION ON THE UTILIZATION OF

- Page 331 and 332:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 333 and 334:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 335 and 336:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 337 and 338:

3. Results and discussions WOOD SCI

- Page 339 and 340:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 341:

Abadlia ......................... 3

- Page 345 and 346:

ANNEX 1: FACTS ABOUT COST ACTION IE

- Page 347 and 348:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 349 and 350:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 351 and 352:

Keynote presentations WOOD SCIENCE

- Page 353 and 354:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 355 and 356:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 357 and 358:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 359 and 360:

WOOD SCIENCE FOR CONSERVATION OF CU

- Page 362:

Finito di stampare presso Grafiche