Characterization and control of the fiber-matrix interface in ceramic ...

Characterization and control of the fiber-matrix interface in ceramic ...

Characterization and control of the fiber-matrix interface in ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

20<br />

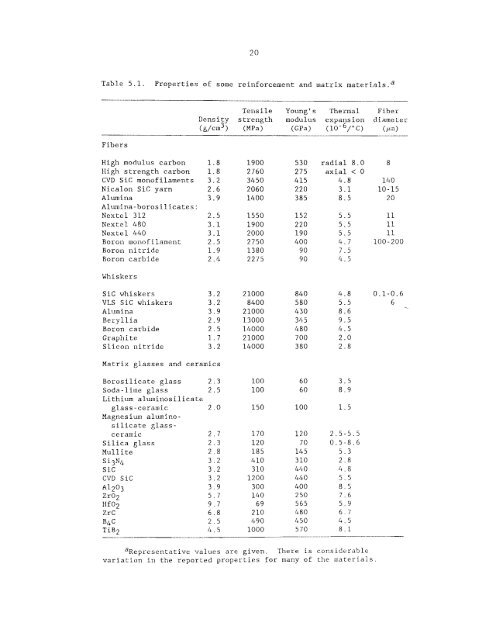

Table 5.1.<br />

Properties <strong>of</strong> some re<strong>in</strong>forcement <strong>and</strong> <strong>matrix</strong> materi.nls.a<br />

'Tensile Young's Thermal Fiber<br />

Density strength modulus expansion diameter<br />

( g/cm3) (MPa) (GPa) (10-6/oC) (p<strong>in</strong>)<br />

Fibers<br />

High modulus carbon<br />

High strength carbon<br />

CVD Sic mon<strong>of</strong>ilaments<br />

Nicalon Sic yarn<br />

AI um<strong>in</strong>a<br />

Alum i na - bo r o s i 1 i c a t c: s<br />

Nextel 312<br />

Nextel 480<br />

Nextel 440<br />

Boron mono filament<br />

Boron nitride<br />

Boron carbide<br />

1.8<br />

1.8<br />

3.2<br />

2.6<br />

3.9<br />

2.5<br />

3.1<br />

3.1<br />

2.5<br />

1.9<br />

2.4<br />

1900<br />

3.760<br />

3450<br />

2060<br />

1400<br />

1550<br />

1900<br />

2000<br />

2750<br />

1380<br />

2275<br />

530<br />

275<br />

415<br />

220<br />

385<br />

152<br />

220<br />

190<br />

400<br />

90<br />

90<br />

radial 8.0 8<br />

axial < 0<br />

4.8 1GO<br />

3.1 10-15<br />

8.5 20<br />

5.5 11<br />

5.5 11<br />

5.5 11<br />

4.7 100-200<br />

7.5<br />

/+. 5<br />

Whiskers<br />

Sic whiskers<br />

VIS Sic whiskers<br />

Almi na<br />

Beryllia<br />

Boron carbide<br />

Graphite<br />

Slicon nitride<br />

3.2<br />

3.2<br />

3.9<br />

2.9<br />

2.5<br />

1.7<br />

3.2<br />

21000<br />

8400<br />

21000<br />

13000<br />

1.4000<br />

21000<br />

14000<br />

840<br />

580<br />

430<br />

3h5<br />

Lr80<br />

700<br />

380<br />

4.8 0.1-0.6<br />

5.5 6<br />

8.6<br />

9.5<br />

4.5<br />

2.0<br />

2.8<br />

-<br />

t4atri.x glasses <strong>and</strong> <strong>ceramic</strong>s<br />

Borosilicate glass 2.3<br />

Soda-lime glass 2.5<br />

Lithium alum<strong>in</strong>osilicate<br />

glass-<strong>ceramic</strong> 2.0<br />

Magnes iun alum<strong>in</strong>o -<br />

silicate glass<strong>ceramic</strong><br />

2.7<br />

Silica glass 2.3<br />

Mu1 1 i te 2.8<br />

Si3N4 3.2<br />

Sic 3.2<br />

CVD Sic 3.2<br />

A1203 3.9<br />

Zr02 5.7<br />

Hf02 9.7<br />

ZrC 6.8<br />

B4C 2.5<br />

TiR2 4.5<br />

1.00<br />

100<br />

150<br />

170<br />

120<br />

185<br />

410<br />

310<br />

1200<br />

300<br />

140<br />

69<br />

2 10<br />

490<br />

1000<br />

60<br />

60<br />

100<br />

120<br />

70<br />

145<br />

310<br />

440<br />

440<br />

400<br />

2 50<br />

565<br />

480<br />

450<br />

570<br />

.<br />

3.5<br />

8.9<br />

1.5<br />

2.5-5.5<br />

0.5-8.6<br />

5.3<br />

2.8<br />

4.8<br />

5.5<br />

8.5<br />

7.6<br />

5.9<br />

6.7<br />

4.5<br />

8.1<br />

aRepresentative TJalues are given. There is considerable<br />

variation <strong>in</strong> <strong>the</strong> reported propercies for many <strong>of</strong> <strong>the</strong> materials