Year : 2010-11 - CCL

Year : 2010-11 - CCL

Year : 2010-11 - CCL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

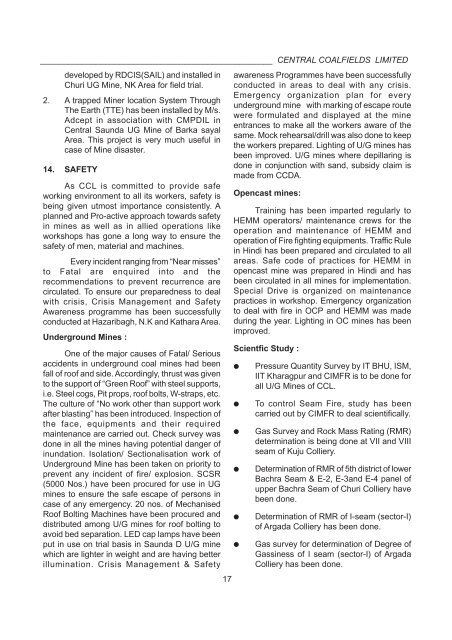

__________________________________________________ CENTRAL COALFIELDS LIMITED<br />

developed by RDCIS(SAIL) and installed in<br />

Churi UG Mine, NK Area for field trial.<br />

2. A trapped Miner location System Through<br />

The Earth (TTE) has been installed by M/s.<br />

Adcept in association with CMPDIL in<br />

Central Saunda UG Mine of Barka sayal<br />

Area. This project is very much useful in<br />

case of Mine disaster.<br />

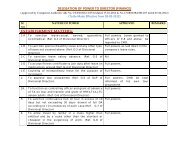

14. SAFETY<br />

As <strong>CCL</strong> is committed to provide safe<br />

working environment to all its workers, safety is<br />

being given utmost importance consistently. A<br />

planned and Pro-active approach towards safety<br />

in mines as well as in allied operations like<br />

workshops has gone a long way to ensure the<br />

safety of men, material and machines.<br />

Every incident ranging from “Near misses”<br />

to Fatal are enquired into and the<br />

recommendations to prevent recurrence are<br />

circulated. To ensure our preparedness to deal<br />

with crisis, Crisis Management and Safety<br />

Awareness programme has been successfully<br />

conducted at Hazaribagh, N.K and Kathara Area.<br />

Underground Mines :<br />

One of the major causes of Fatal/ Serious<br />

accidents in underground coal mines had been<br />

fall of roof and side. Accordingly, thrust was given<br />

to the support of “Green Roof” with steel supports,<br />

i.e. Steel cogs, Pit props, roof bolts, W-straps, etc.<br />

The culture of “No work other than support work<br />

after blasting” has been introduced. Inspection of<br />

the face, equipments and their required<br />

maintenance are carried out. Check survey was<br />

done in all the mines having potential danger of<br />

inundation. Isolation/ Sectionalisation work of<br />

Underground Mine has been taken on priority to<br />

prevent any incident of fire/ explosion. SCSR<br />

(5000 Nos.) have been procured for use in UG<br />

mines to ensure the safe escape of persons in<br />

case of any emergency. 20 nos. of Mechanised<br />

Roof Bolting Machines have been procured and<br />

distributed among U/G mines for roof bolting to<br />

avoid bed separation. LED cap lamps have been<br />

put in use on trial basis in Saunda D U/G mine<br />

which are lighter in weight and are having better<br />

illumination. Crisis Management & Safety<br />

17<br />

awareness Programmes have been successfully<br />

conducted in areas to deal with any crisis.<br />

Emergency organization plan for every<br />

underground mine with marking of escape route<br />

were formulated and displayed at the mine<br />

entrances to make all the workers aware of the<br />

same. Mock rehearsal/drill was also done to keep<br />

the workers prepared. Lighting of U/G mines has<br />

been improved. U/G mines where depillaring is<br />

done in conjunction with sand, subsidy claim is<br />

made from CCDA.<br />

Opencast mines:<br />

Training has been imparted regularly to<br />

HEMM operators/ maintenance crews for the<br />

operation and maintenance of HEMM and<br />

operation of Fire fighting equipments. Traffic Rule<br />

in Hindi has been prepared and circulated to all<br />

areas. Safe code of practices for HEMM in<br />

opencast mine was prepared in Hindi and has<br />

been circulated in all mines for implementation.<br />

Special Drive is organized on maintenance<br />

practices in workshop. Emergency organization<br />

to deal with fire in OCP and HEMM was made<br />

during the year. Lighting in OC mines has been<br />

improved.<br />

Scientfic Study :<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

Pressure Quantity Survey by IT BHU, ISM,<br />

IIT Kharagpur and CIMFR is to be done for<br />

all U/G Mines of <strong>CCL</strong>.<br />

To control Seam Fire, study has been<br />

carried out by CIMFR to deal scientifically.<br />

Gas Survey and Rock Mass Rating (RMR)<br />

determination is being done at VII and VIII<br />

seam of Kuju Colliery.<br />

Determination of RMR of 5th district of lower<br />

Bachra Seam & E-2, E-3and E-4 panel of<br />

upper Bachra Seam of Churi Colliery have<br />

been done.<br />

Determination of RMR of I-seam (sector-I)<br />

of Argada Colliery has been done.<br />

Gas survey for determination of Degree of<br />

Gassiness of I seam (sector-I) of Argada<br />

Colliery has been done.