Evaluation and Repair of Wrought Iron and - Purdue e-Pubs ...

Evaluation and Repair of Wrought Iron and - Purdue e-Pubs ...

Evaluation and Repair of Wrought Iron and - Purdue e-Pubs ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

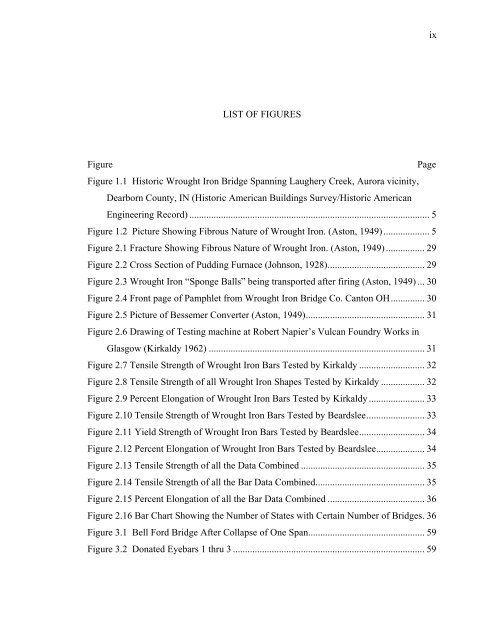

ixLIST OF FIGURESFigurePageFigure 1.1 Historic <strong>Wrought</strong> <strong>Iron</strong> Bridge Spanning Laughery Creek, Aurora vicinity,Dearborn County, IN (Historic American Buildings Survey/Historic AmericanEngineering Record) ................................................................................................... 5Figure 1.2 Picture Showing Fibrous Nature <strong>of</strong> <strong>Wrought</strong> <strong>Iron</strong>. (Aston, 1949)................... 5Figure 2.1 Fracture Showing Fibrous Nature <strong>of</strong> <strong>Wrought</strong> <strong>Iron</strong>. (Aston, 1949)................ 29Figure 2.2 Cross Section <strong>of</strong> Pudding Furnace (Johnson, 1928)........................................ 29Figure 2.3 <strong>Wrought</strong> <strong>Iron</strong> “Sponge Balls” being transported after firing (Aston, 1949) ... 30Figure 2.4 Front page <strong>of</strong> Pamphlet from <strong>Wrought</strong> <strong>Iron</strong> Bridge Co. Canton OH.............. 30Figure 2.5 Picture <strong>of</strong> Bessemer Converter (Aston, 1949)................................................. 31Figure 2.6 Drawing <strong>of</strong> Testing machine at Robert Napier’s Vulcan Foundry Works inGlasgow (Kirkaldy 1962) ......................................................................................... 31Figure 2.7 Tensile Strength <strong>of</strong> <strong>Wrought</strong> <strong>Iron</strong> Bars Tested by Kirkaldy ........................... 32Figure 2.8 Tensile Strength <strong>of</strong> all <strong>Wrought</strong> <strong>Iron</strong> Shapes Tested by Kirkaldy .................. 32Figure 2.9 Percent Elongation <strong>of</strong> <strong>Wrought</strong> <strong>Iron</strong> Bars Tested by Kirkaldy ....................... 33Figure 2.10 Tensile Strength <strong>of</strong> <strong>Wrought</strong> <strong>Iron</strong> Bars Tested by Beardslee........................ 33Figure 2.11 Yield Strength <strong>of</strong> <strong>Wrought</strong> <strong>Iron</strong> Bars Tested by Beardslee........................... 34Figure 2.12 Percent Elongation <strong>of</strong> <strong>Wrought</strong> <strong>Iron</strong> Bars Tested by Beardslee.................... 34Figure 2.13 Tensile Strength <strong>of</strong> all the Data Combined ................................................... 35Figure 2.14 Tensile Strength <strong>of</strong> all the Bar Data Combined............................................. 35Figure 2.15 Percent Elongation <strong>of</strong> all the Bar Data Combined ........................................ 36Figure 2.16 Bar Chart Showing the Number <strong>of</strong> States with Certain Number <strong>of</strong> Bridges. 36Figure 3.1 Bell Ford Bridge After Collapse <strong>of</strong> One Span................................................ 59Figure 3.2 Donated Eyebars 1 thru 3 ............................................................................... 59