Evaluation and Repair of Wrought Iron and - Purdue e-Pubs ...

Evaluation and Repair of Wrought Iron and - Purdue e-Pubs ...

Evaluation and Repair of Wrought Iron and - Purdue e-Pubs ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

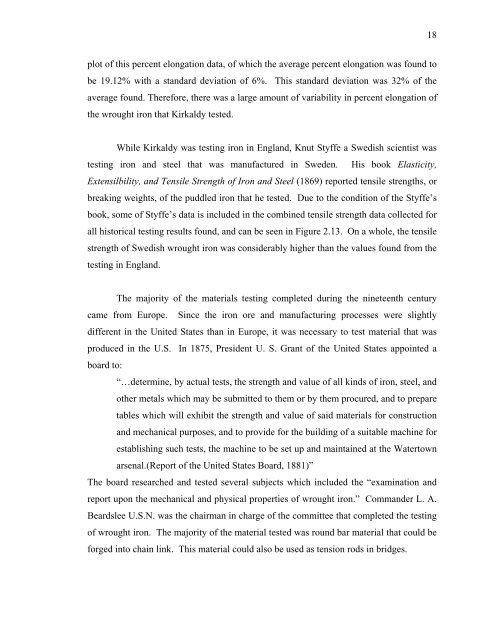

18plot <strong>of</strong> this percent elongation data, <strong>of</strong> which the average percent elongation was found tobe 19.12% with a st<strong>and</strong>ard deviation <strong>of</strong> 6%. This st<strong>and</strong>ard deviation was 32% <strong>of</strong> theaverage found. Therefore, there was a large amount <strong>of</strong> variability in percent elongation <strong>of</strong>the wrought iron that Kirkaldy tested.While Kirkaldy was testing iron in Engl<strong>and</strong>, Knut Styffe a Swedish scientist wastesting iron <strong>and</strong> steel that was manufactured in Sweden. His book Elasticity,Extensilbility, <strong>and</strong> Tensile Strength <strong>of</strong> <strong>Iron</strong> <strong>and</strong> Steel (1869) reported tensile strengths, orbreaking weights, <strong>of</strong> the puddled iron that he tested. Due to the condition <strong>of</strong> the Styffe’sbook, some <strong>of</strong> Styffe’s data is included in the combined tensile strength data collected forall historical testing results found, <strong>and</strong> can be seen in Figure 2.13. On a whole, the tensilestrength <strong>of</strong> Swedish wrought iron was considerably higher than the values found from thetesting in Engl<strong>and</strong>.The majority <strong>of</strong> the materials testing completed during the nineteenth centurycame from Europe. Since the iron ore <strong>and</strong> manufacturing processes were slightlydifferent in the United States than in Europe, it was necessary to test material that wasproduced in the U.S. In 1875, President U. S. Grant <strong>of</strong> the United States appointed aboard to:“…determine, by actual tests, the strength <strong>and</strong> value <strong>of</strong> all kinds <strong>of</strong> iron, steel, <strong>and</strong>other metals which may be submitted to them or by them procured, <strong>and</strong> to preparetables which will exhibit the strength <strong>and</strong> value <strong>of</strong> said materials for construction<strong>and</strong> mechanical purposes, <strong>and</strong> to provide for the building <strong>of</strong> a suitable machine forestablishing such tests, the machine to be set up <strong>and</strong> maintained at the Watertownarsenal.(Report <strong>of</strong> the United States Board, 1881)”The board researched <strong>and</strong> tested several subjects which included the “examination <strong>and</strong>report upon the mechanical <strong>and</strong> physical properties <strong>of</strong> wrought iron.” Comm<strong>and</strong>er L. A.Beardslee U.S.N. was the chairman in charge <strong>of</strong> the committee that completed the testing<strong>of</strong> wrought iron. The majority <strong>of</strong> the material tested was round bar material that could beforged into chain link. This material could also be used as tension rods in bridges.