Boiler Manual - Weil-McLain

Boiler Manual - Weil-McLain

Boiler Manual - Weil-McLain

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

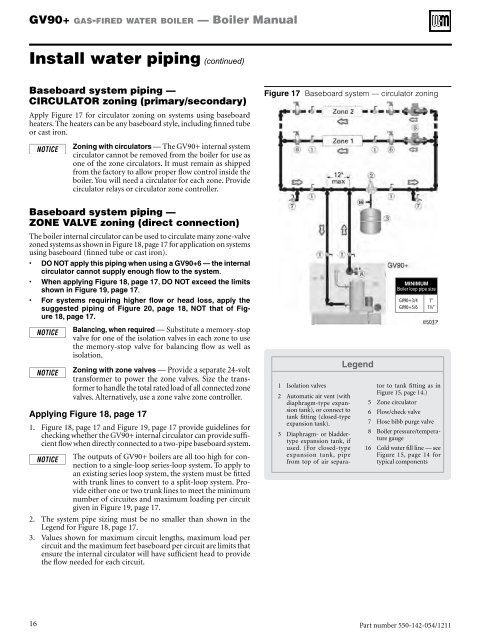

GV90+ gas-fired water boiler — <strong>Boiler</strong> <strong>Manual</strong>Install water piping (continued)Baseboard system piping —CIRCULATOR zoning (primary/secondary)Apply Figure 17 for circulator zoning on systems using baseboardheaters. The heaters can be any baseboard style, including finned tubeor cast iron.Figure 17 Baseboard system — circulator zoningZoning with circulators — The GV90+ internal systemcirculator cannot be removed from the boiler for use asone of the zone circulators. It must remain as shippedfrom the factory to allow proper flow control inside theboiler. You will need a circulator for each zone. Providecirculator relays or circulator zone controller.Baseboard system piping —ZONE VALVE zoning (direct connection)The boiler internal circulator can be used to circulate many zone-valvezoned systems as shown in Figure 18, page 17 for application on systemsusing baseboard (finned tube or cast iron).• DO NOT apply this piping when using a GV90+6 — the internalcirculator cannot supply enough flow to the system.• When applying Figure 18, page 17, DO NOT exceed the limitsshown in Figure 19, page 17.• For systems requiring higher flow or head loss, apply thesuggested piping of Figure 20, page 18, NOT that of Figure18, page 17.Balancing, when required — Substitute a memory-stopvalve for one of the isolation valves in each zone to usethe memory-stop valve for balancing flow as well asisolation.Zoning with zone valves — Provide a separate 24-volttransformer to power the zone valves. Size the transformerto handle the total rated load of all connected zonevalves. Alternatively, use a zone valve zone controller.Applying Figure 18, page 171. Figure 18, page 17 and Figure 19, page 17 provide guidelines forchecking whether the GV90+ internal circulator can provide sufficientflow when directly connected to a two-pipe baseboard system.The outputs of GV90+ boilers are all too high for connectionto a single-loop series-loop system. To apply toan existing series loop system, the system must be fittedwith trunk lines to convert to a split-loop system. Provideeither one or two trunk lines to meet the minimumnumber of circuites and maximum loading per circuitgiven in Figure 19, page 17.2. The system pipe sizing must be no smaller than shown in theLegend for Figure 18, page 17.3. Values shown for maximum circuit lengths, maximum load percircuit and the maximum feet baseboard per circuit are limits thatensure the internal circulator will have sufficient head to providethe flow needed for each circuit.LegendMINIMUM<strong>Boiler</strong> loop pipe sizeGV90+3/4GV90+5/61”1¼”1 Isolation valves2 Automatic air vent (withdiaphragm-type expansiontank), or connect totank fitting (closed-typeexpansion tank).3 Diaphragm- or bladdertypeexpansion tank, ifused. (For closed-typeexpansion tank, pipefrom top of air separatorto tank fitting as inFigure 15, page 14.)5 Zone circulator6 Flow/check valve7 Hose bibb purge valve8 <strong>Boiler</strong> pressure/temperaturegauge16 Cold water fill line — seeFigure 15, page 14 fortypical components16Part number 550-142-054/1211