standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

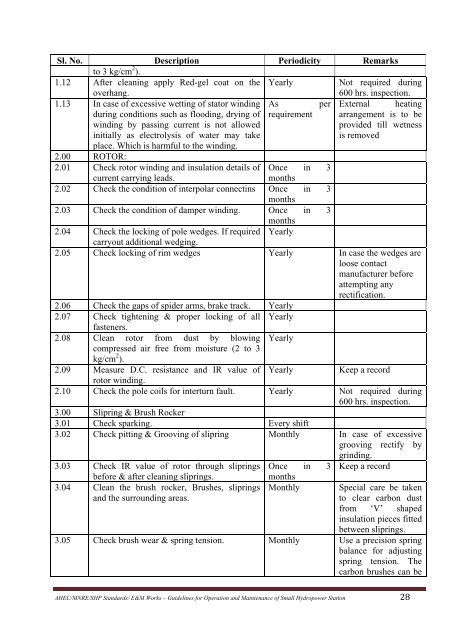

Sl. No. Description Periodicity Remarksto 3 kg/cm 2 ).1.12 After cleaning apply Red-gel coat on the YearlyNot required duringoverhang.600 hrs. inspection.1.13 In case of excessive wetting of stator winding As per External heatingduring conditions such as flooding, drying ofwinding by passing current is not allowedinitially as electrolysis of water may takeplace. Which is harmful to the winding.requirement arrangement is to beprovided till wetnessis removed2.00 ROTOR:2.01 Check rotor winding and insulation details ofcurrent carrying leads.Once in 3months2.02 Check the condition of interpolar connectins Once in 3months2.03 Check the condition of damper winding. Once in 3months2.04 Check the locking of pole wedges. If required Yearlycarryout additional wedging.2.05 Check locking of rim wedges Yearly In case the wedges areloose contactmanufacturer be<strong>for</strong>eattempting anyrectification.2.06 Check the gaps of spider arms, brake track. Yearly2.07 Check tightening & proper locking of allfasteners.2.08 Clean rotor from dust by blowingcompressed air free from moisture (2 to 3kg/cm 2 ).YearlyYearly2.09 Measure D.C. resistance and IR value of YearlyKeep a recordrotor winding.2.10 Check the pole coils <strong>for</strong> interturn fault. Yearly Not required during600 hrs. inspection.3.00 Slipring & Brush Rocker3.01 Check sparking. Every shift3.02 Check pitting & Grooving of slipring Monthly In case of excessivegrooving rectify bygrinding.3.03 Check IR value of rotor through slipringsbe<strong>for</strong>e & after cleaning sliprings.3.04 Clean the brush rocker, Brushes, slipringsand the surrounding areas.Once in 3monthsMonthlyKeep a recordSpecial care be takento clear carbon dustfrom ‘V’ shapedinsulation pieces fittedbetween sliprings.3.05 Check brush wear & spring tension. Monthly Use a precision springbalance <strong>for</strong> adjustingspring tension. Thecarbon brushes can be<strong>AHEC</strong>/MNRE/SHP Standards/ E&M Works – Guidelines <strong>for</strong> Operation and Maintenance of Small Hydropower Station 28