standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

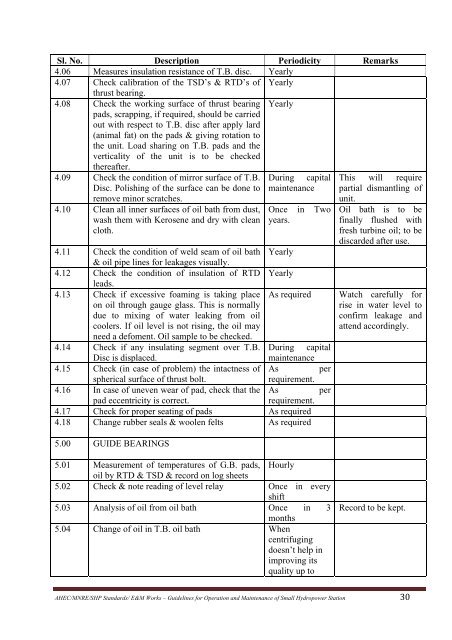

Sl. No. Description Periodicity Remarks4.06 Measures insulation resistance of T.B. disc. Yearly4.07 Check calibration of the TSD’s & RTD’s of Yearlythrust bearing.4.08 Check the working surface of thrust bearing Yearlypads, scrapping, if required, should be carriedout with respect to T.B. disc after apply lard(animal fat) on the pads & giving rotation tothe unit. Load sharing on T.B. pads and theverticality of the unit is to be checkedthereafter.4.09 Check the condition of mirror surface of T.B. During capitalDisc. Polishing of the surface can be done to maintenanceremove minor scratches.unit.4.10 Clean all inner surfaces of oil bath from dust, Once in Twowash them with Kerosene and dry with clean years.cloth.4.11 Check the condition of weld seam of oil bath Yearly& oil pipe lines <strong>for</strong> leakages visually.4.12 Check the condition of insulation of RTD Yearlyleads.4.13 Check if excessive foaming is taking place As requiredon oil through gauge glass. This is normallydue to mixing of water leaking from oilcoolers. If oil level is not rising, the oil mayneed a defoment. Oil sample to be checked.4.14 Check if any insulating segment over T.B. During capitalDisc is displaced.maintenance4.15 Check (in case of problem) the intactness of As perspherical surface of thrust bolt.requirement.4.16 In case of uneven wear of pad, check that the As perpad eccentricity is correct.requirement.4.17 Check <strong>for</strong> proper seating of pads As required4.18 Change rubber seals & woolen felts As required5.00 GUIDE BEARINGSThis will requirepartial dismantling ofOil bath is to befinally flushed withfresh turbine oil; to bediscarded after use.Watch carefully <strong>for</strong>rise in water level toconfirm leakage andattend accordingly.5.01 Measurement of temperatures of G.B. pads, Hourlyoil by RTD & TSD & record on log sheets5.02 Check & note reading of level relay Once in everyshift5.03 Analysis of oil from oil bath Once in 3months5.04 Change of oil in T.B. oil bath Whencentrifugingdoesn’t help inimproving itsquality up toRecord to be kept.<strong>AHEC</strong>/MNRE/SHP Standards/ E&M Works – Guidelines <strong>for</strong> Operation and Maintenance of Small Hydropower Station 30