standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

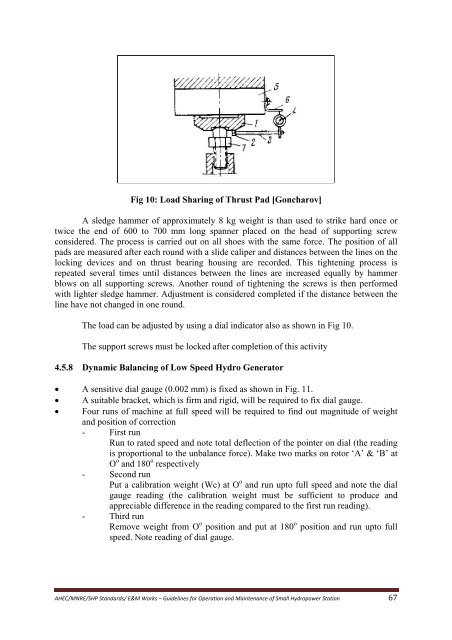

Fig 10: Load Sharing of Thrust Pad [Goncharov]A sledge hammer of approximately 8 kg weight is than used to strike hard once ortwice the end of 600 to 700 mm long spanner placed on the head of supporting screwconsidered. The process is carried out on all shoes with the same <strong>for</strong>ce. The position of allpads are measured after each round with a slide caliper and distances between the lines on thelocking devices and on thrust bearing housing are recorded. This tightening process isrepeated several times until distances between the lines are increased equally by hammerblows on all supporting screws. Another round of tightening the screws is then per<strong>for</strong>medwith lighter sledge hammer. Adjustment is considered completed if the distance between theline have not changed in one round.The load can be adjusted by using a dial indicator also as shown in Fig 10.The support screws must be locked after completion of this activity4.5.8 Dynamic Balancing of Low Speed Hydro Generator• A sensitive dial gauge (0.002 mm) is fixed as shown in Fig. 11.• A suitable bracket, which is firm and rigid, will be required to fix dial gauge.• Four runs of machine at full speed will be required to find out magnitude of weightand position of correction- First runRun to rated speed and note total deflection of the pointer on dial (the readingis proportional to the unbalance <strong>for</strong>ce). Make two marks on rotor ‘A’ & ‘B’ atO o and 180 o respectively- Second runPut a calibration weight (Wc) at O o and run upto full speed and note the dialgauge reading (the calibration weight must be sufficient to produce andappreciable difference in the reading compared to the first run reading).- Third runRemove weight from O o position and put at 180 o position and run upto fullspeed. Note reading of dial gauge.<strong>AHEC</strong>/MNRE/SHP Standards/ E&M Works – Guidelines <strong>for</strong> Operation and Maintenance of Small Hydropower Station 67