standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

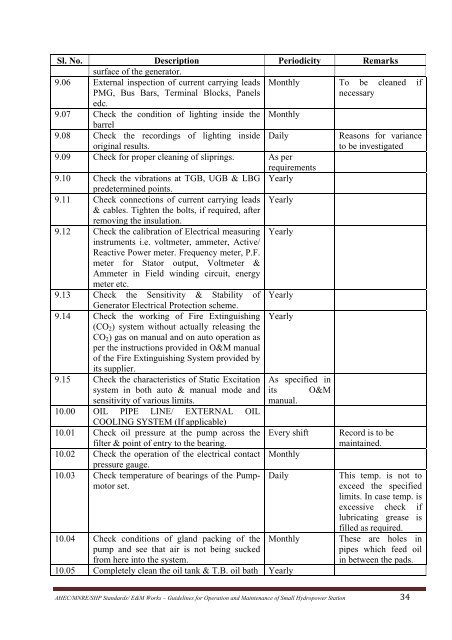

Sl. No. Description Periodicity Remarkssurface of the generator.9.06 External inspection of current carrying leads Monthly To be cleaned ifPMG, Bus Bars, Terminal Blocks, Panelsnecessaryedc.9.07 Check the condition of lighting inside the Monthlybarrel9.08 Check the recordings of lighting inside Dailyoriginal results.9.09 Check <strong>for</strong> proper cleaning of sliprings. As perrequirements9.10 Check the vibrations at TGB, UGB & LBG Yearlypredetermined points.9.11 Check connections of current carrying leads Yearly& cables. Tighten the bolts, if required, afterremoving the insulation.9.12 Check the calibration of Electrical measuringinstruments i.e. voltmeter, ammeter, Active/Reactive Power meter. Frequency meter, P.F.meter <strong>for</strong> Stator output, Voltmeter &Ammeter in Field winding circuit, energymeter etc.9.13 Check the Sensitivity & Stability ofGenerator Electrical Protection scheme.9.14 Check the working of Fire Extinguishing(CO 2 ) system without actually releasing theCO 2 ) gas on manual and on auto operation asper the instructions provided in O&M manualof the Fire Extinguishing System provided byits supplier.9.15 Check the characteristics of Static Excitationsystem in both auto & manual mode andsensitivity of various limits.10.00 OIL PIPE LINE/ EXTERNAL OILCOOLING SYSTEM (If applicable)10.01 Check oil pressure at the pump across thefilter & point of entry to the bearing.10.02 Check the operation of the electrical contactpressure gauge.10.03 Check temperature of bearings of the Pumpmotorset.YearlyYearlyYearlyAs specified inits O&Mmanual.Every shiftMonthlyDaily10.04 Check conditions of gland packing of the Monthlypump and see that air is not being suckedfrom here into the system.10.05 Completely clean the oil tank & T.B. oil bath YearlyReasons <strong>for</strong> varianceto be investigatedRecord is to bemaintained.This temp. is not toexceed the specifiedlimits. In case temp. isexcessive check iflubricating grease isfilled as required.These are holes inpipes which feed oilin between the pads.<strong>AHEC</strong>/MNRE/SHP Standards/ E&M Works – Guidelines <strong>for</strong> Operation and Maintenance of Small Hydropower Station 34