standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

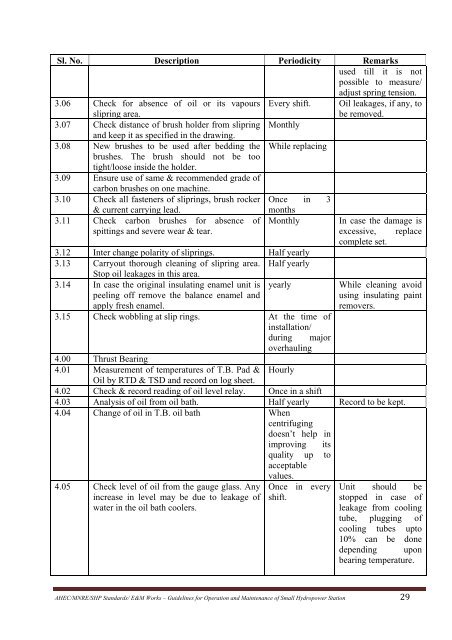

Sl. No. Description Periodicity Remarksused till it is notpossible to measure/adjust spring tension.3.06 Check <strong>for</strong> absence of oil or its vapours Every shift. Oil leakages, if any, toslipring area.be removed.3.07 Check distance of brush holder from slipring Monthlyand keep it as specified in the drawing.3.08 New brushes to be used after bedding the While replacingbrushes. The brush should not be tootight/loose inside the holder.3.09 Ensure use of same & recommended grade ofcarbon brushes on one machine.3.10 Check all fasteners of sliprings, brush rocker Once in 3& current carrying lead.3.11 Check carbon brushes <strong>for</strong> absence ofspittings and severe wear & tear.monthsMonthlyIn case the damage isexcessive, replacecomplete set.3.12 Inter change polarity of sliprings. Half yearly3.13 Carryout thorough cleaning of slipring area. Half yearlyStop oil leakages in this area.3.14 In case the original insulating enamel unit ispeeling off remove the balance enamel andapply fresh enamel.yearlyWhile cleaning avoidusing insulating paintremovers.3.15 Check wobbling at slip rings. At the time ofinstallation/during majoroverhauling4.00 Thrust Bearing4.01 Measurement of temperatures of T.B. Pad & HourlyOil by RTD & TSD and record on log sheet.4.02 Check & record reading of oil level relay. Once in a shift4.03 Analysis of oil from oil bath. Half yearly Record to be kept.4.04 Change of oil in T.B. oil bath Whencentrifugingdoesn’t help in4.05 Check level of oil from the gauge glass. Anyincrease in level may be due to leakage ofwater in the oil bath coolers.improving itsquality up toacceptablevalues.Once in everyshift.Unit should bestopped in case ofleakage from coolingtube, plugging ofcooling tubes upto10% can be donedepending uponbearing temperature.<strong>AHEC</strong>/MNRE/SHP Standards/ E&M Works – Guidelines <strong>for</strong> Operation and Maintenance of Small Hydropower Station 29