standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

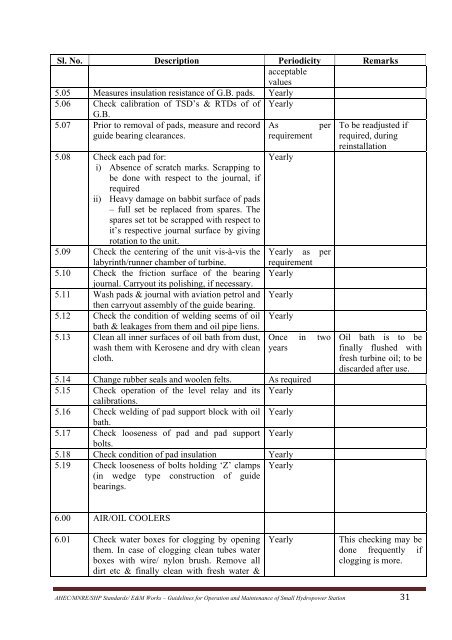

Sl. No. Description Periodicity Remarksacceptablevalues5.05 Measures insulation resistance of G.B. pads. Yearly5.06 Check calibration of TSD’s & RTDs of of YearlyG.B.5.07 Prior to removal of pads, measure and recordguide bearing clearances.5.08 Check each pad <strong>for</strong>:i) Absence of scratch marks. Scrapping tobe done with respect to the journal, ifrequiredii) Heavy damage on babbit surface of pads– full set be replaced from spares. Thespares set tot be scrapped with respect toit’s respective journal surface by givingrotation to the unit.5.09 Check the centering of the unit vis-à-vis thelabyrinth/runner chamber of turbine.5.10 Check the friction surface of the bearingjournal. Carryout its polishing, if necessary.5.11 Wash pads & journal with aviation petrol andthen carryout assembly of the guide bearing.5.12 Check the condition of welding seems of oilbath & leakages from them and oil pipe liens.5.13 Clean all inner surfaces of oil bath from dust,wash them with Kerosene and dry with cleancloth.AsrequirementYearlyperYearly as perrequirementYearlyYearlyYearlyOnce in twoyears5.14 Change rubber seals and woolen felts. As required5.15 Check operation of the level relay and its Yearlycalibrations.5.16 Check welding of pad support block with oil Yearlybath.5.17 Check looseness of pad and pad support Yearlybolts.5.18 Check condition of pad insulation Yearly5.19 Check looseness of bolts holding ‘Z’ clamps(in wedge type construction of guidebearings.YearlyTo be readjusted ifrequired, duringreinstallationOil bath is to befinally flushed withfresh turbine oil; to bediscarded after use.6.00 AIR/OIL COOLERS6.01 Check water boxes <strong>for</strong> clogging by openingthem. In case of clogging clean tubes waterboxes with wire/ nylon brush. Remove alldirt etc & finally clean with fresh water &YearlyThis checking may bedone frequently ifclogging is more.<strong>AHEC</strong>/MNRE/SHP Standards/ E&M Works – Guidelines <strong>for</strong> Operation and Maintenance of Small Hydropower Station 31