standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

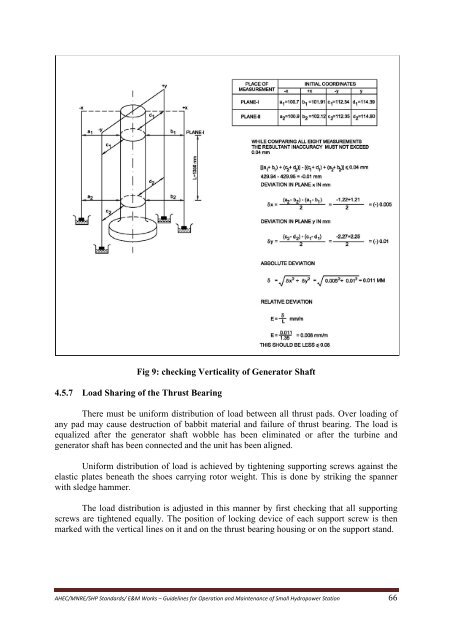

Fig 9: checking Verticality of Generator Shaft4.5.7 Load Sharing of the Thrust BearingThere must be uni<strong>for</strong>m distribution of load between all thrust pads. Over loading ofany pad may cause destruction of babbit material and failure of thrust bearing. The load isequalized after the generator shaft wobble has been eliminated or after the turbine andgenerator shaft has been connected and the unit has been aligned.Uni<strong>for</strong>m distribution of load is achieved by tightening supporting screws against theelastic plates beneath the shoes carrying rotor weight. This is done by striking the spannerwith sledge hammer.The load distribution is adjusted in this manner by first checking that all supportingscrews are tightened equally. The position of locking device of each support screw is thenmarked with the vertical lines on it and on the thrust bearing housing or on the support stand.<strong>AHEC</strong>/MNRE/SHP Standards/ E&M Works – Guidelines <strong>for</strong> Operation and Maintenance of Small Hydropower Station 66