standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

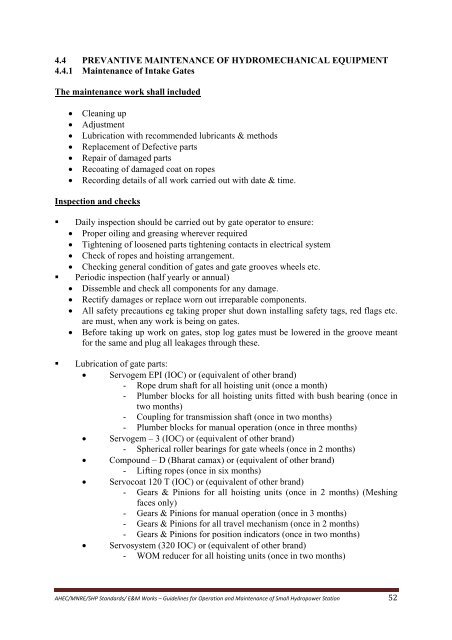

4.4 PREVANTIVE MAINTENANCE OF HYDROMECHANICAL EQUIPMENT4.4.1 Maintenance of Intake GatesThe maintenance work shall included• Cleaning up• Adjustment• Lubrication with recommended lubricants & methods• Replacement of Defective parts• Repair of damaged parts• Recoating of damaged coat on ropes• Recording details of all work carried out with date & time.Inspection and checks• Daily inspection should be carried out by gate operator to ensure:• Proper oiling and greasing wherever required• Tightening of loosened parts tightening contacts in electrical system• Check of ropes and hoisting arrangement.• Checking general condition of gates and gate grooves wheels etc.• Periodic inspection (half yearly or annual)• Dissemble and check all components <strong>for</strong> any damage.• Rectify damages or replace worn out irreparable components.• All safety precautions eg taking proper shut down installing safety tags, red flags etc.are must, when any work is being on gates.• Be<strong>for</strong>e taking up work on gates, stop log gates must be lowered in the groove meant<strong>for</strong> the same and plug all leakages through these.• Lubrication of gate parts:• Servogem EPI (IOC) or (equivalent of other brand)- Rope drum shaft <strong>for</strong> all hoisting unit (once a month)- Plumber blocks <strong>for</strong> all hoisting units fitted with bush bearing (once intwo months)- Coupling <strong>for</strong> transmission shaft (once in two months)- Plumber blocks <strong>for</strong> manual operation (once in three months)• Servogem – 3 (IOC) or (equivalent of other brand)- Spherical roller bearings <strong>for</strong> gate wheels (once in 2 months)• Compound – D (Bharat camax) or (equivalent of other brand)- Lifting ropes (once in six months)• Servocoat 120 T (IOC) or (equivalent of other brand)- Gears & Pinions <strong>for</strong> all hoisting units (once in 2 months) (Meshingfaces only)- Gears & Pinions <strong>for</strong> manual operation (once in 3 months)- Gears & Pinions <strong>for</strong> all travel mechanism (once in 2 months)- Gears & Pinions <strong>for</strong> position indicators (once in two months)• Servosystem (320 IOC) or (equivalent of other brand)- WOM reducer <strong>for</strong> all hoisting units (once in two months)<strong>AHEC</strong>/MNRE/SHP Standards/ E&M Works – Guidelines <strong>for</strong> Operation and Maintenance of Small Hydropower Station 52