standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

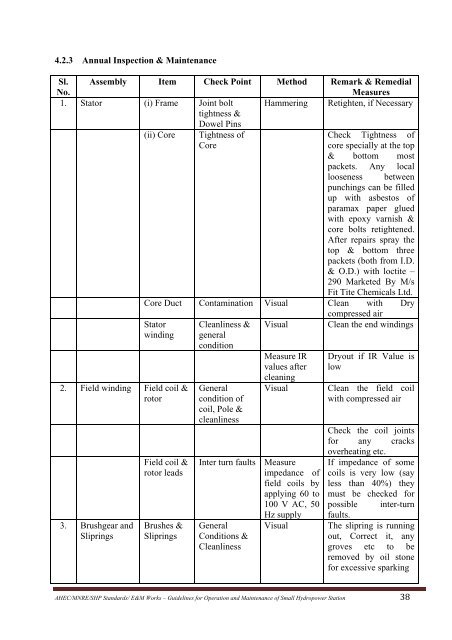

4.2.3 Annual Inspection & MaintenanceSl.No.Assembly Item Check Point Method Remark & RemedialMeasures1. Stator (i) Frame Joint bolt Hammering Retighten, if Necessarytightness &Dowel Pins(ii) Core Tightness ofCheck Tightness ofCorecore specially at the top& bottom mostpackets. Any locallooseness betweenpunchings can be filledup with asbestos ofparamax paper gluedwith epoxy varnish &core bolts retightened.After repairs spray thetop & bottom threepackets (both from I.D.& O.D.) with loctite –290 Marketed By M/sFit Tite Chemicals Ltd.Core Duct Contamination Visual Clean with Drycompressed airStatorwinding2. Field winding Field coil &rotor3. Brushgear andSlipringsField coil &rotor leadsBrushes &SlipringsCleanliness &generalconditionGeneralcondition ofcoil, Pole &cleanlinessVisualMeasure IRvalues aftercleaningVisualInter turn faults Measureimpedance offield coils byapplying 60 to100 V AC, 50Hz supplyGeneral VisualConditions &CleanlinessClean the end windingsDryout if IR Value islowClean the field coilwith compressed airCheck the coil joints<strong>for</strong> any cracksoverheating etc.If impedance of somecoils is very low (sayless than 40%) theymust be checked <strong>for</strong>possible inter-turnfaults.The slipring is runningout, Correct it, anygroves etc to beremoved by oil stone<strong>for</strong> excessive sparking<strong>AHEC</strong>/MNRE/SHP Standards/ E&M Works – Guidelines <strong>for</strong> Operation and Maintenance of Small Hydropower Station 38