standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

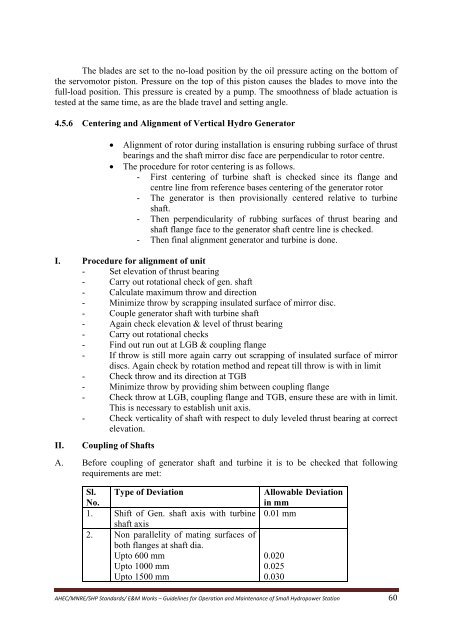

The blades are set to the no-load position by the oil pressure acting on the bottom ofthe servomotor piston. Pressure on the top of this piston causes the blades to move into thefull-load position. This pressure is created by a pump. The smoothness of blade actuation istested at the same time, as are the blade travel and setting angle.4.5.6 Centering and Alignment of Vertical Hydro Generator• Alignment of rotor during installation is ensuring rubbing surface of thrustbearings and the shaft mirror disc face are perpendicular to rotor centre.• The procedure <strong>for</strong> rotor centering is as follows.- First centering of turbine shaft is checked since its flange andcentre line from reference bases centering of the generator rotor- The generator is then provisionally centered relative to turbineshaft.- Then perpendicularity of rubbing surfaces of thrust bearing andshaft flange face to the generator shaft centre line is checked.- Then final alignment generator and turbine is done.I. Procedure <strong>for</strong> alignment of unit- Set elevation of thrust bearing- Carry out rotational check of gen. shaft- Calculate maximum throw and direction- Minimize throw by scrapping insulated surface of mirror disc.- Couple generator shaft with turbine shaft- Again check elevation & level of thrust bearing- Carry out rotational checks- Find out run out at LGB & coupling flange- If throw is still more again carry out scrapping of insulated surface of mirrordiscs. Again check by rotation method and repeat till throw is with in limit- Check throw and its direction at TGB- Minimize throw by providing shim between coupling flange- Check throw at LGB, coupling flange and TGB, ensure these are with in limit.This is necessary to establish unit axis.- Check verticality of shaft with respect to duly leveled thrust bearing at correctelevation.II.Coupling of ShaftsA. Be<strong>for</strong>e coupling of generator shaft and turbine it is to be checked that followingrequirements are met:Sl. Type of DeviationNo.1. Shift of Gen. shaft axis with turbineshaft axis2. Non parallelity of mating surfaces ofboth flanges at shaft dia.Upto 600 mmUpto 1000 mmUpto 1500 mmAllowable Deviationin mm0.01 mm0.0200.0250.030<strong>AHEC</strong>/MNRE/SHP Standards/ E&M Works – Guidelines <strong>for</strong> Operation and Maintenance of Small Hydropower Station 60