- Page 1:

THESISPRESENTED ATNATIONAL GRADUATE

- Page 4 and 5:

As the human civilization progress

- Page 6 and 7:

CHAPTER - 1 SELF-HEALING POLYMERIC

- Page 8:

8.1.5 Atomic Force Microscopy …

- Page 11 and 12:

Synthetic engineering materials in

- Page 13 and 14:

esponse to a specific external stim

- Page 15 and 16:

The first work based on this approa

- Page 17 and 18:

een prepared from urea-formaldehyde

- Page 19 and 20:

monomer systems. The addition of EN

- Page 21 and 22:

Figure - 1.10: Self-healing process

- Page 23 and 24:

was required to reach healing effic

- Page 25 and 26:

In addition to above works, some ot

- Page 27 and 28:

that have been identified to be tak

- Page 29 and 30:

part of the chapter, these material

- Page 31 and 32:

Figure - 1.17: Self-healing of the

- Page 33 and 34:

commercialized under tradenames; Nu

- Page 35 and 36:

joined together at temperature high

- Page 37 and 38:

Inspired by these findings, the fir

- Page 39 and 40:

temperature greater than 80 o C in

- Page 41 and 42:

Figure - 1.27: Sulfur chemistry bas

- Page 43 and 44:

A different kind of sulfur chemistr

- Page 45 and 46:

Figure - 1.29: Dynamic covalent che

- Page 47 and 48:

cracks. The recovered droplets afte

- Page 49 and 50:

23 White, S. R. et al. Autonomic he

- Page 51 and 52:

65 Taber, D. F. & Frankowski, K. J.

- Page 53 and 54:

107 Kushner, A. M., Vossler, J. D.,

- Page 55:

148 Park, J. S., Kim, H. S. & Hahn,

- Page 58 and 59:

The value of subscripts “n”,

- Page 60 and 61:

The formation of spherical micelles

- Page 62 and 63:

the micelle assembly showed the pre

- Page 64 and 65:

gain onto the electrodes by buildin

- Page 66 and 67:

The resistance R can be further exp

- Page 68 and 69:

empty-tower velocity U only depends

- Page 70 and 71: This apparent morphological switchi

- Page 72 and 73: In a further qualitative analysis,

- Page 74 and 75: noteworthy and though its feasibili

- Page 76 and 77: Furthermore within this range, lowe

- Page 78 and 79: Figure - 2.22: Scanning Electron Mi

- Page 80 and 81: While the resistance measurements g

- Page 82 and 83: In conclusion, a self-healing membr

- Page 84 and 85: 23 Giacomelli, F. C., Riegel, I. C.

- Page 86 and 87: micelles enabled the membrane to se

- Page 88 and 89: The second class is represented by

- Page 90 and 91: To avoid the probable clogging of t

- Page 92 and 93: 181614SP2 - iNumber of Particles121

- Page 94 and 95: 1000900800y = 3E+06xR² = 0,9911y =

- Page 96 and 97: very high value of 1.5 g.l -1 . Thi

- Page 98 and 99: Since the only change in the membra

- Page 100 and 101: 100Retention (%)8060400,100,20,40,6

- Page 102 and 103: Figure - 3.18: Scanning Electron Mi

- Page 104 and 105: (Figure - 3.20). A cursory look at

- Page 106 and 107: When compared to poly(styrene) NPs,

- Page 108 and 109: Figure - 3.24: Scanning Electron Mi

- Page 110 and 111: REFERENCES1 Metzler, R. & Klafter,

- Page 112 and 113: 46 Bemporad, D., Luttmann, C. & Ess

- Page 114 and 115: In this chapter, preparation of 3D

- Page 116 and 117: obtain complex macromolecular archi

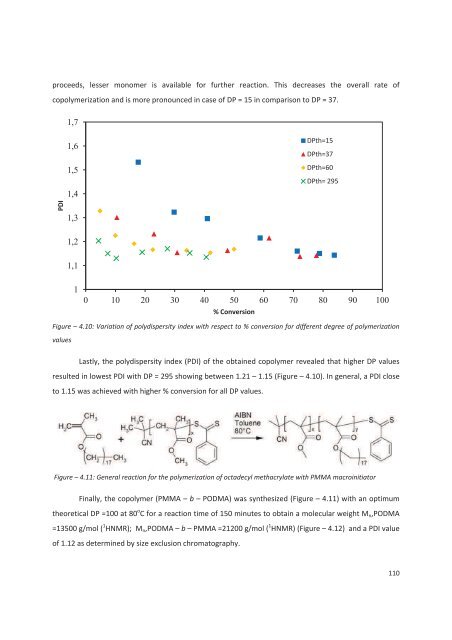

- Page 118 and 119: The polymerization was conducted at

- Page 122 and 123: mg/ml),the micelles’ hydrodynamic

- Page 124 and 125: Figure - 4.15: The monolayer and mu

- Page 126 and 127: monolayer of micelles and topmost l

- Page 128 and 129: The presence of the dispersed micel

- Page 130 and 131: Heating the multilayer micelle asse

- Page 132 and 133: stable zipping of the micelles. Mul

- Page 134 and 135: 24 Moad, G., Rizzardo, E. & Thang,

- Page 136 and 137: The concept of nano-gel based self-

- Page 138 and 139: Figure - 5.4: Size distribution of

- Page 140 and 141: In a typical process, the two compo

- Page 142 and 143: Figure - 5.10: 1HNMR spectra obtain

- Page 144 and 145: The 1 HNMR spectrum obtained for th

- Page 146 and 147: REFERENCES1 White, S. R. et al. Aut

- Page 148 and 149: healing ability shown by the membra

- Page 150 and 151: 7. PERSPECTIVESBeing the first such

- Page 153 and 154: 8. MATERIALS & METHODSThis chapter

- Page 155 and 156: 8.1.3 PEG Filtration MeasurementsTh

- Page 157 and 158: addition of TEOS due to formation o

- Page 159 and 160: solution was ultrasonicated for 15

- Page 161 and 162: Triethylamine (TEA) (Sigma-Aldrich

- Page 163 and 164: To prepare the monolayer assembly o

- Page 165 and 166: was added followed by addition of 0

- Page 168 and 169: ELABORATION OF SELF-HEALING POLYMER

- Page 170 and 171:

ELABORATION DES MEMBRANES POLYMERES