4(%3)3 - Ecole nationale supérieure de chimie de Montpellier

4(%3)3 - Ecole nationale supérieure de chimie de Montpellier

4(%3)3 - Ecole nationale supérieure de chimie de Montpellier

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

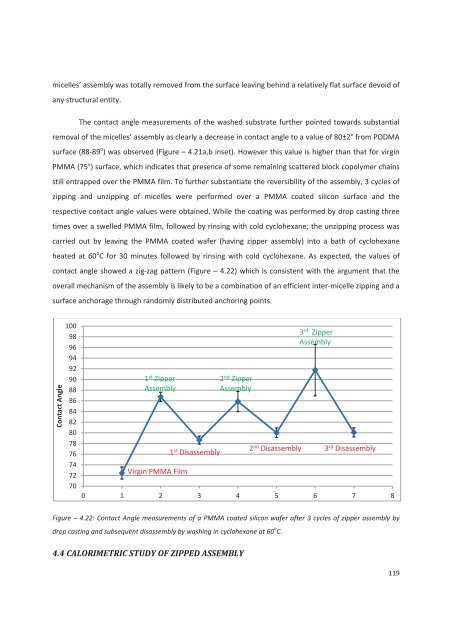

micelles’ assembly was totally removed from the surface leaving behind a relatively flat surface <strong>de</strong>void ofany structural entity.The contact angle measurements of the washed substrate further pointed towards substantialremoval of the micelles’ assembly as clearly a <strong>de</strong>crease in contact angle to a value of 80±2° from PODMAsurface (88-89 o ) was observed (Figure – 4.21a,b inset). However this value is higher than that for virginPMMA (75°) surface, which indicates that presence of some remaining scattered block copolymer chainsstill entrapped over the PMMA film. To further substantiate the reversibility of the assembly, 3 cycles ofzipping and unzipping of micelles were performed over a PMMA coated silicon surface and therespective contact angle values were obtained. While the coating was performed by drop casting threetimes over a swelled PMMA film, followed by rinsing with cold cyclohexane; the unzipping process wascarried out by leaving the PMMA coated wafer (having zipper assembly) into a bath of cyclohexaneheated at 60 o C for 30 minutes followed by rinsing with cold cyclohexane. As expected, the values ofcontact angle showed a zig-zag pattern (Figure – 4.22) which is consistent with the argument that theoverall mechanism of the assembly is likely to be a combination of an efficient inter-micelle zipping and asurface anchorage through randomly distributed anchoring points.Contact Angle1009896949290888684828078767472701 st ZipperAssemblyVirgin PMMA Film1 st Disassembly2 nd ZipperAssembly3 rd ZipperAssembly2 nd Disassembly 3 rd Disassembly0 1 2 3 4 5 6 7 8Figure – 4.22: Contact Angle measurements of a PMMA coated silicon wafer after 3 cycles of zipper assembly bydrop casting and subsequent disassembly by washing in cyclohexane at 60 o C.4.4 CALORIMETRIC STUDY OF ZIPPED ASSEMBLY119