4(%3)3 - Ecole nationale supérieure de chimie de Montpellier

4(%3)3 - Ecole nationale supérieure de chimie de Montpellier

4(%3)3 - Ecole nationale supérieure de chimie de Montpellier

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

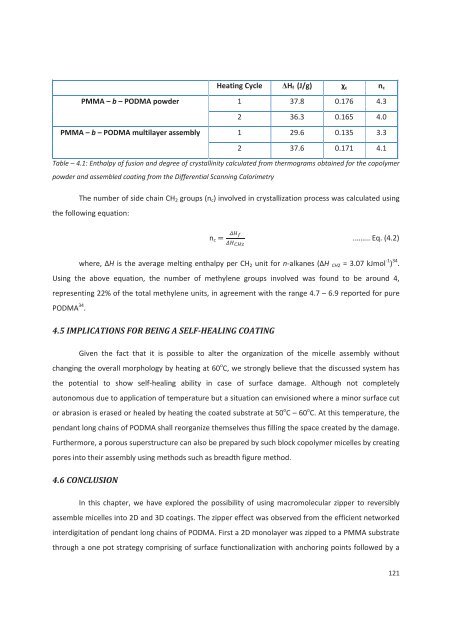

Heating Cycle H f (J/g) c n cPMMA – b – PODMA pow<strong>de</strong>r 1 37.8 0.176 4.32 36.3 0.165 4.0PMMA – b – PODMA multilayer assembly 1 29.6 0.135 3.32 37.6 0.171 4.1Table – 4.1: Enthalpy of fusion and <strong>de</strong>gree of crystallinity calculated from thermograms obtained for the copolymerpow<strong>de</strong>r and assembled coating from the Differential Scanning CalorimetryThe number of si<strong>de</strong> chain CH 2 groups (n c ) involved in crystallization process was calculated usingthe following equation:n c = .…….. Eq. (4.2)H is the average melting enthalpy per CH 2 unit for n-H CH2 = 3.07 kJmol -1 ) 34 .Using the above equation, the number of methylene groups involved was found to be around 4,representing 22% of the total methylene units, in agreement with the range 4.7 – 6.9 reported for purePODMA 34 .4.5 IMPLICATIONS FOR BEING A SELF-HEALING COATINGGiven the fact that it is possible to alter the organization of the micelle assembly withoutchanging the overall morphology by heating at 60 o C, we strongly believe that the discussed system hasthe potential to show self-healing ability in case of surface damage. Although not completelyautonomous due to application of temperature but a situation can envisioned where a minor surface cutor abrasion is erased or healed by heating the coated substrate at 50 o C – 60 o C. At this temperature, thependant long chains of PODMA shall reorganize themselves thus filling the space created by the damage.Furthermore, a porous superstructure can also be prepared by such block copolymer micelles by creatingpores into their assembly using methods such as breadth figure method.4.6 CONCLUSIONIn this chapter, we have explored the possibility of using macromolecular zipper to reversiblyassemble micelles into 2D and 3D coatings. The zipper effect was observed from the efficient networkedinterdigitation of pendant long chains of PODMA. First a 2D monolayer was zipped to a PMMA substratethrough a one pot strategy comprising of surface functionalization with anchoring points followed by a121