4(%3)3 - Ecole nationale supérieure de chimie de Montpellier

4(%3)3 - Ecole nationale supérieure de chimie de Montpellier

4(%3)3 - Ecole nationale supérieure de chimie de Montpellier

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

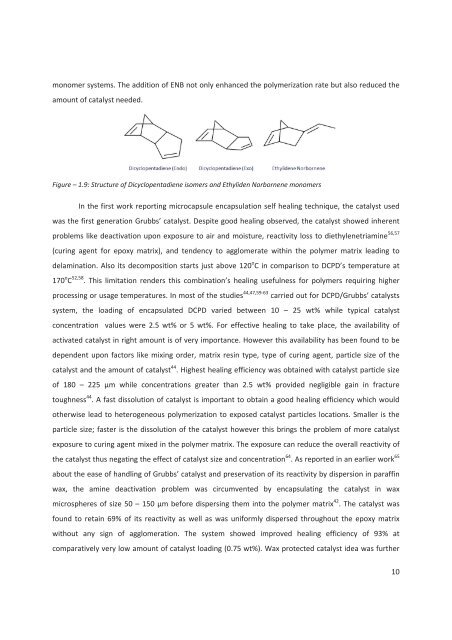

monomer systems. The addition of ENB not only enhanced the polymerization rate but also reduced theamount of catalyst nee<strong>de</strong>d.Figure – 1.9: Structure of Dicyclopentadiene isomers and Ethyli<strong>de</strong>n Norbornene monomersIn the first work reporting microcapsule encapsulation self healing technique, the catalyst usedwas the first generation Grubbs’ catalyst. Despite good healing observed, the catalyst showed inherentproblems like <strong>de</strong>activation upon exposure to air and moisture, reactivity loss to diethylenetriamine 56,57(curing agent for epoxy matrix), and ten<strong>de</strong>ncy to agglomerate within the polymer matrix leading to<strong>de</strong>lamination. Also its <strong>de</strong>composition starts just above 120 o C in comparison to DCPD’s temperature at170 o C 52,58 . This limitation ren<strong>de</strong>rs this combination’s healing usefulness for polymers requiring higherprocessing or usage temperatures. In most of the studies 44,47,59-63 carried out for DCPD/Grubbs’ catalystssystem, the loading of encapsulated DCPD varied between 10 – 25 wt% while typical catalystconcentration values were 2.5 wt% or 5 wt%. For effective healing to take place, the availability ofactivated catalyst in right amount is of very importance. However this availability has been found to be<strong>de</strong>pen<strong>de</strong>nt upon factors like mixing or<strong>de</strong>r, matrix resin type, type of curing agent, particle size of thecatalyst and the amount of catalyst 44 . Highest healing efficiency was obtained with catalyst particle sizeof 180 – 225 µm while concentrations greater than 2.5 wt% provi<strong>de</strong>d negligible gain in fracturetoughness 44 . A fast dissolution of catalyst is important to obtain a good healing efficiency which wouldotherwise lead to heterogeneous polymerization to exposed catalyst particles locations. Smaller is theparticle size; faster is the dissolution of the catalyst however this brings the problem of more catalystexposure to curing agent mixed in the polymer matrix. The exposure can reduce the overall reactivity ofthe catalyst thus negating the effect of catalyst size and concentration 64 . As reported in an earlier work 65about the ease of handling of Grubbs’ catalyst and preservation of its reactivity by dispersion in paraffinwax, the amine <strong>de</strong>activation problem was circumvented by encapsulating the catalyst in waxmicrospheres of size 50 – 150 µm before dispersing them into the polymer matrix 42 . The catalyst wasfound to retain 69% of its reactivity as well as was uniformly dispersed throughout the epoxy matrixwithout any sign of agglomeration. The system showed improved healing efficiency of 93% atcomparatively very low amount of catalyst loading (0.75 wt%). Wax protected catalyst i<strong>de</strong>a was further10